Development of optical components and modules designed for next generation optical communication/optical transmission systems

Backgrounds and Technologies that Support TDK's Development of Optical Communication Components and Modules

As seen in the strategies such as "Industry 4.0" from Germany and "Society 5.0" from Japan, the world is proactively moving forward to create new manufacturing approaches, new services, and new values using the technologies including IoT, M2M, AI, and VR. An ultra-smart society in which everything is connected via the Internet or sensor technologies is waiting for you in the near future.

TDK develops not only material technology as its core technology, but also thin-film process technology, wafer processing technology, and multilayer technology for manufacturing HDD heads, DVDs, BDs, and so on. Making full use of these technologies, TDK has developed various components for optical communication and delivered millions of optical components and devices for construction of Fiber to the Home (FTTH).

Furthermore, with the advantage of having both electronics and optics technologies, TDK has been working on miniaturization and modularization of key devices used for branch sections of optical communication networks. This article introduces the latest achievement of TDK through such efforts; the "LN thin-film" that opens up new application possibilities of LN (LiNbO3: Lithium Niobate) materials.

CONTENTS

Technical Background

Overview of optical communication/optical transmission systems

A new evolutionary stage has begun for optical communication networks to process explosively increasing traffic resulting from the spread of the Internet and associated high speed transmission of large capacity content. In data centers, reduction of enormous electrical power consumed by communication equipment and air conditioning is problematic for the future growth of the cloud computing, Internet of Things (IoT), and machine-to-machine (M2M). Optical transmission systems featuring low power dissipation and high-speed large capacity transmission are being introduced to overcome these problems.

Clearly, the performance of next generation optical communication/optical transmission devices will depend on various optical transmission equipment and the performance and quality of the optical components within such devices. As networks and systems expand, the scale of optical transmission devices will grow larger, and the number of installations will increase in parallel. Therefore, the importance of saving space and power through miniature and high-density packaging will grow more and more. At the same time, optical components are evolving into modularized and/or arrayed ones, and further into optical integrated circuit instead of merely miniaturizing conventional discrete optical components.

The configuration of a typical optical communication network is shown in Fig. 1. The backbone network is comprised of a core network that connects towns and cities, as well as an urban area sized metropolitan network. The subscriber accesses networks such as FTTH (Fiber to the Home) branch from the metropolitan network.

In an optical communication system, various advanced technologies such as digital coherence, DWDM (Dense Wavelength Division Multiplexing), and ROADM (Reconfigurable Optical Add-Drop Multiplexer) have been introduced to realize power-savings and to improve the economics of high-speed and large-capacity transmission networks.

DWDM : Dense Wavelength Division Multiplexing ROADM : Reconfigurable Optical Add-Drop Multiplexer

Fig. 1 Configuration of Optical Communication Network

Key technologies that contributed to development of optical communication systems

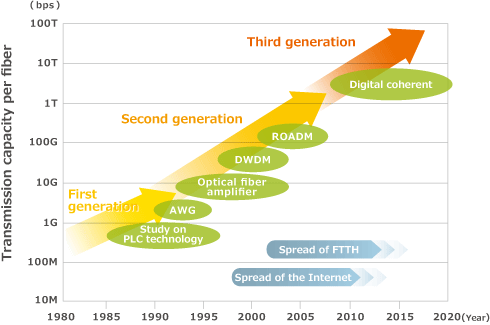

Long distance communications using optical fibers has been feasible since the 1970s when low-loss optical fiber was invented following semiconductor lasers and photo-diodes; these three fundamental technologies enabled optical communications. The first generation of practical optical communication systems were developed in the 1980s, and the second generation appeared in the decades of the 1990s and 2000s. The third generation is now under way.

Key technologies resulted in advances of the optical communication system are as follows:

- PLC (Planar Lightwave Circuit)

A PLC is a device in which an integrated optical waveguide is fabricated onto a flat substrate using photolithographic processes similar to methods established by the LSI industry. The optical waveguides have similar transmission characteristics as optical fibers. Transmission in an optical fiber is based upon differences in the refractive index. In the1980s, the fundamental technologies were researched, and by the 1990s practical PLC devices such as an AWG (Arrayed Waveguide Grating) were developed. - Optical Amplifier / EDFA (Erbium-doped Fiber Amplifier)

Though transmission losses in optical fibers are very low, since they cannot be avoided, relays need to be installed in long-distance transmissions. An optical amplifier is a device for boosting optical signal levels without the need to perform optical to electrical conversions. The optical amplifier uses a special optical fiber containing the element of erbium (Er), is referred to as an EDFA (Erbium-doped fiber amplifier). The EDFA is critical to realize long distance transmission such as the transoceanic optical cables. - WDM (Wavelength Division Multiplexing) Technology

WDM is a technology that combines signals of multiple wavelengths onto a single optical fiber for long distance transmission. DWDM (Dense WDM: Dense Wavelength Division Multiplexing) technology further improves upon WDM technology by allowing an extremely large numbers of wavelength (and therefore an extremely large amount of data) to be transmitted by a single optical fiber. - AWG (Arrayed Waveguide Grating)

A signal multiplexed by WDM/DWDM technology has to be separated (branched) into individual channels having the original plurality of wavelengths at the receiving side of an optical terminal. The AWG is an optical device that plays a role as an optical multiplexer/demultiplexer. The AWG was developed on PLC technology platform in 1990s. - ROADM (Reconfigurable Optical Add-Drop Multiplexer)

A ROADM is a device that instantly and flexibly creates optical paths for optical signals of certain wavelength in an optical fiber communication network by software. With ROADM, flexible and efficient network operation that enables high-speed transmission of large-capacity data is feasible by controlling the drop, add, and through conditions of optical paths remotely to form virtual detours and new networks. - OXC (Optical Cross Connect)

OXC is a network connection technology evolved from ROADM. By employing large-scale optical switches, OXC devices used for branch or other sections in mesh core networks can cross-connect large-capacity signals without converting them. - Digital Coherent Optical Transmission technology

Digital Coherent Optical Transmission is a technology which allows highly reliable long-distance transmission of extremely large data capacity within a single optical fiber. It is achieved by introducing advanced digital signal processing (DSP) technology into the optical communication scheme. It is one of the key technologies for realizing near-future optical communication networks. - WSS (Wavelength Selective Switch)

A WSS is an optical device that switches and sorts a wavelength multiplexed optical signals. It allows network operators to direct discrete wavelengths to specific output ports on the order of milliseconds. Key components of the WSS are optical multiplexer/demultiplexer, an MEMS mirror, input/output fibers, etc. It is an advanced technology commonly used for sophisticated ROADM systems.

Through various technical innovations, FTTH has also become widely deployed since initial deployments began shortly after the Year 2000. In parallel, an optical communication network has evolved that serves as the infrastructure that supports the ICT society. Fig. 2 shows the transition of optical communication technology correlated the expansion of transmission capacity.

Fig. 2 Progress in Optical Communication Technology and Transition of Transmission Capacity

Various Optical Components and Devices Supporting Optical Communication/Optical Transmission Systems

As the optical communication network expands beyond the core and metropolitan networks and the optical transmission systems in data centers evolve with the growth of the cloud computing, the performance, quality, and reliability of optical components and devices used for interconnection, branching, and amplification have become extremely important. Such interconnection, branching, and amplification components and devices have become as critical to network operation as the fundamental elements (namely the semiconductor laser, the photo diode, and the optical fiber) are.

The primary optical components and devices that support the optical communication/optical transmission system are as follows:

| Optical connector | When connecting optical fibers to each other, minute core sections through which the light passes are butted together. An optical connector is an optical component mounted onto the end of an optical fiber to facilitate the alignment and connection between fibers. |

| Optical splitter | An optical splitter is an optical component for branching a single optical fiber into multiple optical fibers. In FTTH, 1x32 splitter, 1x8 splitter, and 1x4 splitter are commonly used. |

| Optical isolator | When light is reflected on the interface of the connected sections of an optical communication system, back reflected light may occur resulting in false operation and line noise. An optical isolator allows only one-way passage of light to prevent back reflections. |

| Optical switch | An optical switch is component for switching the path of an optical signal. Switching may be realized mechanically, by electro-optical effect, or thermo-optic effect. |

| Optical Multiplexer / Demultiplexer | An optical multiplexer / demultiplexer combines optical signals of multiple wavelengths into a single optical fiber and demultiplexes (separates) the transmitted optical signal to single wavelengths onto individual fibers. The optical multiplexer / demultiplexer is a critical component in optical WDM (wavelength multiplexed)/DWDM (high density WDM) systems. |

| Optical integrated circuit | An optical integrated circuit is a device into which multiple components such as semiconductor lasers and optical switches are integrated on a substrate. LSI manufacturing technologies such as CVD and photolithography are utilized to fabricate such devices. |

| Optical fiber array | An optical fiber array is a device for precisely arranging multiple optical fibers and connecting them to the optical waveguides of an optical splitter and so on. To minimize transmission loss, extremely advanced high-precision processing technology and assembly technology are required. |

| Optical modulator | An optical modulator is a device that converts an electric signal to an optical signal. Some optical modulators make use of an electro-optic effect of EO polymers or ferroelectric materials such as LN (Lithium Niobate). |

| Tap-PD module | Tap-PD module is an optical power monitor that measures the intensity of the optical signals using photo detectors (PD), after tapping some input signals transmitted via optical fibers. There is a growing need for arrayed miniature Tap-PD modules. |

TDK's Advantage in Optical Component and Device Technologies

Several millions of optical components are delivered for construction of FTTH networks

TSince the beginning of 1990s, TDK has developed and commercialized various optical components, including optical isolators.

The optical isolator uses a phenomenon called Faraday rotation to cancel the influence of reflected light (return light) to make only forward directed optical signal pass through the device. Along with the optical splitter, the optical isolator has been designed into many optical communication systems including FTTH networks.

Various technologies which differ from those of electronic component manufacturing are necessary for the commercialization of optical components and devices. TDK can advantageously draw upon a comprehensive set of core technologies accumulated over many years including know-how in the following disciplines: materials technology, process technology, evaluation and simulation technology, device and module technology and production engineering.

TDK technologies supporting optical communication/optical transmission technology are collectively introduced as follows;

- A unique, comprehensive set of technical capabilities based on the accumulated core technologies

HDD heads are manufactured by forming nanometer order head elements on a wafer making use of highly advanced thin-film processing technology. The next generation of HDDs will utilize a laser mounted thermal assist magnetic head.

» » Related Information: Five core technologies of TDKFig. 3 Structure of TMR Element of HDD Head and Principle of Thermal Assist Magnetic Recording

- Production engineering that optimizes QCD (Quality, Cost, and Delivery) in the most effective way

In an optical communication/transmission system, the number of relays and branch sections increases as a network and/or system expands. Therefore, the quality and performance of the optical components and devices used within the system have an ever-increasing effect on the performance of the entire network. TDK's production engineering optimizes QCD (Quality, Cost, and Delivery) though manufacturing experience of electronic components and devices such as HDD heads and multilayer ceramic chip capacitors and provides the high standard of quality and reliability required for the manufacture of optical components and devices. This includes the optical fiber arrays produced by TDK. - In-house manufacturing of production and inspection apparatuses

TDK has not only developed a unique manufacturing method of electronic components and devices including capacitors and inductors, but also manufactured many manufacturing equipment in-house for commercialization. In the development of various optical components and devices, many manufacturing and inspection equipment are manufactured in-house.

Next Generation Optical Components/Optical Modules That TDK Strives For

With the prevalence of the Internet and smartphones and the evolution of IoT and M2M, communication traffic has explosively increased over the past several years and will continue to grow into the future. In order to manage such explosive growth, the optical communication system is migrating into the era of terabit (Tbps) transmission and petabit (Pbps) transmission. In data centers and high performance computing (HPC), interconnections for transmitting electrical signals remain the bottleneck. The developments of solutions that connect devices and circuits by optical transmission system are progressing and further advancement of advanced technologies such as silicon photonics (Si photonics) technology is expected.

In preparation for a next generation optical communication/optical transmission system, not only miniaturization, high integration, and energy saving but also excellent quality, performance, and reliability are required for optical components and devices.

Based on the thin-film processing technology, wafer processing technology, multilayer technology, nanometer order ultra-precision processing technology, and ultra-precision packaging of micro optics components cultivated by manufacturing HDD heads, DVDs, and BDs, TDK has successfully developed "LN crystalline thin-film." The product is expected to make a significant contribution to miniaturization, space saving, and cost reduction of optical communication/transmission devices.

A "LN crystalline thin-film" is an application of LN (LiNbO3: Lithium Niobate), an optical material commonly used for devices such as optical modulators and optical switches, which is realized based on the thin-film processing technology instead of single crystal pull-up method. Since LN thin-films have advantages compared to the crystal pull-up method in terms of mass productivity and cost and are highly compatible with semiconductor or other thin-film electronic components, they can be used for various applications in addition to optical components and devices.

Request for Information, Delivery of Samples

We accommodate the various needs of our customers

Please feel free to contact us through the inquiry link below for information concerning "LN thin-film", characteristics, specifications, or customization of shapes.

Inquiries

[Notes]

*Please send us your inquiries by including your name, company name, and department name.

The personal information that you give us will only be used to respond to you and to provide requested information.

*We may not be able to respond if necessary information is not entered correctly or depending on the contents of your inquiry.

*Our response may take time depending on the contents of your inquiry.

Searching for Attractive Applications of LN (Lithium Niobate) Materials:

1.5 μm-Thick, High-Quality "LN Crystalline Thin-Film"

LN (LiNbO3: Lithium Niobate) is a ferroelectric material with unique characteristics and used for various products. TDK has successfully established a technology to form 1.5 μm thick, high quality "LN crystalline thin-film" that is grown epitaxially on a sapphire substrate. The LN thin-film technology has a potential for unique and attractive applications different from conventional ones.

Major features and applications of TDK's "LN crystalline thin-film"

《Major features》

- Epitaxially grown on sapphire substrates

- Film thickness of 1 μm is realized without cracks and grain boundaries

- Low bending loss

- Properties equivalent to bulk single crystals

《Major applications》

- Optical switches, optical waveguide devices, wavelength converters, light deflectors, and other optics products

- SAW filters, Acousto‐optic (AO) filters

- Ferroelectric memories (FRAM)

- Optical fiber gyroscopes (FOG), optical electric field sensors, and various other sensors

- Others

*TDK's "LN crystalline thin-film" is a unique material that can be used for new application fields where LN crystal has not been used for. With its variety of technologies and process designs, TDK promises to help your product development. Also, TDK is searching for attractive applications of LN crystalline thin-films. Your proposals are always welcomed. TDK's LN crystalline thin-films can be customized according to your desired film thickness and properties. Please feel free to contact us.

CONTENTS

Expectations for LN (Lithium Niobate) materials with superior EO and piezoelectric properties

Optical modulators that convert electric signals to optical signals utilizes the properties of ferroelectric Lithium Niobate (LiNbO3; commonly known as LN). With a certain types of transparent crystalline solids, refractive index changes when an electric field is impressed. This phenomenon is one of the electro-optic (EO) effects. Among the EO effects, the phenomena in which refractive index changes in proportion to the intensity of electric fields are referred to as Pockels effect. One of the indexes used for evaluating the Pockels effect is the electro‐optic constant. Since LN crystals have high electro‐optic constant (which means that LN crystals show large Pockels effects), they are extensively used in various optical devices including optical modulators and optical switches.

Conventionally, the LN elements for such optical devices have been the several hundred μm thick wafers sliced from single-crystal LN ingots grown by the Czochralski method (a pull-up method). With this method, mass production of LN elements with appropriate thickness is costly, and therefore applications of such LN elements are limited to narrow range.

In other words, if we can establish a technology with which high-quality LN crystal elements of appropriate thickness can be mass produced at low cost, we may be able to open up unique application fields.

Establishing a technology to grow LN crystalline thin-film epitaxially

To address the above-mentioned challenge, TDK has newly developed "LN crystalline thin-film." TDK has succeeded in forming extremely high-quality LN crystalline thin-film having the properties equivalent to bulk single crystal, by applying the thin-film processing technology cultivated by manufacturing HDD heads and optical disks such as DVDs and BDs to make LN crystalline thin-film grow epitaxially on a sapphire substrate.

The thickness of thin-films formed by epitaxial growth is usually several nm to several hundred nm orders, but TDK's LN crystalline thin-film has the thickness of 1.5 μm. This is thinner than the ones that are sliced from bulk single crystal and thick enough for various applications. With this thickness, LN crystalline thin-films are expected to be used for various devices in the future. Another advantage of LN crystalline thin-films is that they are highly compatible with semiconductors and other thin-film components.

Since LN crystalline thin-films have unique properties, they are used for various devices of other fields, in addition to the devices of optics field including optical modulators and optical switches. For example, SAW filters utilize the piezoelectricity and FRAM (non-volatile memory) utilize the ferroelectric property of the LN crystalline thin-films. The LN crystalline thin-films developed by TDK have a potential to open up new and unique application fields.

Having low bending loss, optimum for optical waveguide devices

Fig. 8 shows a sample of TDK's LN thin-film formed on a 4-inch diameter sapphire substrate. LN crystal is a trigonal system crystal having the ilmenite structure. The sample shown in the figure below is the film of which c-axis of the crystal is oriented along the direction vertical to the surface of the substrate. Since LN crystalline thin-films grow as twinned crystals in which two LN single crystals are bonded symmetrically, the number of diffraction peaks measured by X-ray diffraction equipment is the number of symmetries x 2 multiplied by 3. The pole figure (diffraction intensity distribution) included in Fig. 8 indicates that the sample LN thin-film has an extremely good crystallinity despite the fact that the film is deposited as thick as 1.5 μm.

Fig. 8 TDK's Newly Developed LN Thin-Film

The TEM (transmission electron microscope) image included in Fig. 8 shows the twin boundary found on the cross-section of the LN crystalline thin-film. With thin-film growing method, the epitaxial growth is successfully going on until the film thickness reaches a certain value, but when the film becomes thicker than that, the arrangement of the atoms may become irregular, the grain boundaries may be formed, and the film may become polycrystal. Grain boundaries found in polycrystals can adversely affect the properties of the thin-film and the cracks that can occur on the LN wafers sliced from single-crystal ingots are problematic. TDK's extremely high-quality LN thin-films are free from such grain boundaries and cracks. In addition, since they have low bending loss, they are optimum for optical waveguide devices.

One more advantage of TDK's LN crystalline thin-film is that it does not need to be polished, whereas LN wafers need polishing processes such as lapping in the finishing stage. Further, since they are produced by thin-film processing, they are ideal for creating miniature, multi-functional, and modularized devices through integration with semiconductors or other thin-film components.

TDK's LN crystalline thin-film is a unique material that can be applied using different approaches from the conventional ones. TDK has successfully established a technology with which high-quality 1.5 μm-thick LN crystalline thin-film can be formed, maximizing the potential of LN material applications.

Request for Information, Delivery of Samples

We accommodate the various needs of our customers

Please feel free to contact us through the inquiry link below for information concerning "LN thin-film", characteristics, specifications, or customization of shapes.

Inquiries

[Notes]

*Please send us your inquiries by including your name, company name, and department name.

The personal information that you give us will only be used to respond to you and to provide requested information.

*We may not be able to respond if necessary information is not entered correctly or depending on the contents of your inquiry.

*Our response may take time depending on the contents of your inquiry.

-

Solving AI Energy Problems with Neuromorphic Technology

Challenge the reduction of AI power consumption using a neuromorphic device utilizing spin memristors developing by TDK. -

Ultrasensitive magnetic sensor detecting one ten-millionth of geomagnetism

Shieldless and easy-to-use device capable of detecting extremely weak magnetic field. -

Thin-film Capacitors Designed for Integration in Circuit Boards, Thickness of 50μm or Less, Flexible and Crack Resistant

Innovations for decoupling capacitors embedded within the circuit board substrate below the LSI chip. -

New Ag-Stacked Transparent Conductive Film

A functional film that contributes to the conservation and creation of energy. -

TDK Biomagnetic Sensor: Effective Alternative to SQUID (Superconducting Quantum Interference Device)

Capable of detecting extremely weak biomagnetic signals at room temperature. The world's first ambient temperature sensor to visualize the heart's magnetic field distribution. -

Optical Components Supporting Next Generation Optical Communication / Optical Transmission System

Backgrounds and technologies that support TDK's development of optical communication components and modules