|

|

|

| Service robots play an increasingly vital role in society, from transportation and warehouse logistics to home entertainment and security. Regardless of their application, they need to sense changes in their surroundings in real-time to ensure safety while providing a positive user experience. To illustrate how various sensor technologies from TDK’s SmartSensor family can be applied in service robots, this article focuses on a robotic vacuum cleaner (RVC).

|

|

|

|

|

|

|

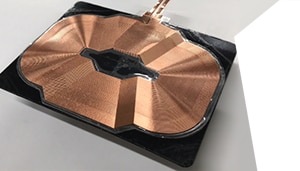

| Introduction to TDK’s New MP-A28 Wireless Power Pattern Coil |

| TDK, a world leader in material technologies, manufacturing and electronic components, has recently developed and released a state-of-the-art, Qi compliant planar wireless power coil utilizing a unique copper patterning technology that provides multiple end-user benefits. The Wireless Power Consortium [WPC] has designated this new coil as MP-A28, while the corresponding TDK part number is WCT38466-N0E0SST01. TDK’s “pattern coil” technology allows for intricate coil patterns that cannot be duplicated by the use of discrete wires and yields tight trace width and gap control normally associated with the finest etching processes and technologies. Also unique to TDK’s technology, is the ease and flexibility to accurately change the copper trace thickness, depending on the application requirements, which is not available by traditional copper coil techniques. |

|

|

|

|

|

|

| High power density solution for DC link on

48 V inverter application with Hybrid Aluminum Electrolytic Capacitors |

| High energy, reliable and volumetric efficient inverters are essential to reducing emissions of vehicles based on 48 V technology. DC-link capacitors can significantly contribute to this target by reducing parasitic losses and increasing thermal efficiency. High inverter powers can be theoretically achieved with multiple capacitor connections. However, a high number of parallel-connected parts also increase the complexity of the system stability. In the field of Aluminum Electrolytic Capacitors, the Hybrid Polymer technology offers higher ripple current densities by a factor of, e.g., 5x compared to standard Liquid Electrolyte technology. By applying the Hybrid Polymer technology to the large axial capacitor can sizes, with solid mechanical construction and special thermal dissipation feature, a compact DC-link solution with a reduced amount of capacitor and minimized thermal escalation risk through stable and efficient thermal design can be achieved. |

|

|

|

|

|

|

|

|