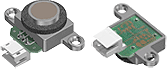

Piezoelectric Powder Level Sensors TSP Series

Sharp Sensitivity that Responds to Subtle Signs

Our TSP series piezoelectric powder level sensors detect the existence of any powder or particulate materials called powder, including wood powder, mineral powder, metal powder, resin powder, fiber filler powder, silica particulate, ceramic particulate, and various coating powders with a high precision at a stable output voltage, unless they are materials that damages or changes the properties of the sensor surface*.

*Since the sensors use a copper alloy on the sensor surface (metal plate of the unimorph oscillator), they cannot be used for applications in which the sensor surface comes to contact with food in Japan in principle, in accordance with the provisions of the Food Sanitation Act.

The particularly notable point with the TSP Series sensors is their sharp sensitivity that allows them to sense the existence of even extremely light and fluffy powder that has taken in air between particles.

This sharp sensitivity, a point that clearly distinguishes the series from other piezoelectric type residue sensors, provides various advantages in applications such as residual amount management of power stockers in production processes for paint, printing ink, dye, or cosmetic products using fine and light powder.

TDK's technologies that contribute to this sensitivity will be explained in the following, in the order of the driving principle, building-in technologies (structure designing), driving method, and circuit technology.

Driving Principle and Structure

The basic driving principle and structure of a piezoelectric oscillation type sensor is the same as those of a piezoelectric sounding body. In the TSP Series sensors, an oscillator having a unimorph structure, in which a disk-shaped piezoelectric ceramics is adhered to a thin metal plate (Figure 2), is adopted.

Figure 2 Structure of piezoelectric unimorph

Driving Principle of Piezoelectric Unimorph

The piezoelectric ceramics have been polarized in the thickness direction in advance; therefore, when voltage is added from outside in the polarization direction, as shown in Figure 3, the entire element expands or contracts in the polarization direction and the thickness increases or decreases. Since its volume does not change, when it extends in the thickness (polarization) direction, it will contract in the polarization and perpendicular directions (diametrical direction). On the other hand, when it contracts in the thickness direction, it extends in the perpendicular direction.

However, as the piezoelectric ceramics are firmly adhered to the metal plate, extension or contraction in the diametrical direction becomes the force that deflects the entire unimorph oscillator, as shown in Figure 4. Therefore, when AC voltage is applied, the unimorph vibrates on the same principle as that of a piezoelectric sounding body.

Application to Piezoelectric Oscillation Type Sensors

As described below, when powder in a fluffy cloud state comes into contact with the vibrating surface of a unimorph, its phase property will change according to the degree of contact, and TDK’s TSP series piezoelectric powder level sensors utilize this phenomenon to detect the existence of powder.

Variations in the peripheral supporting strength have a large impact on the sensing property of the sensor. Therefore, an elastic silicon resin is used for bonding, and the uniformity of the adhesive width and thickness is controlled at a high level (Figure 5).

Driving Method of Piezoelectric Unimorph

As has been described previously, a piezoelectric unimorph is a separately-excited oscillator, in which full-surface electrodes are provided on both sides of piezoelectric ceramics and an AC signal is externally applied to these electrodes. In addition, the signal that determines the existence of the load on the sensor face uses the phase property change of a unimorph.

The equivalent circuit and impedance-frequency characteristic of a piezoelectric unimorph are shown in Figure 6.

Cd represents the capacitance, Lo represents the equivalent weight, Co represents the reciprocal of the equivalent stiffness, and Ro represents the equivalent mechanical resistance. The point where the impedance becomes the smallest in the frequency characteristic is the series resonance point of Lo, Co and Ro in the equivalent circuit.

At this point, the unimorph exhibits inductivity near the resonance point when unloaded, and exhibits capacitivity otherwise. However, as the load applied to the sensor face increases, its phase property gradually changes, and when the load reaches a certain level, it becomes capacitive in all frequency ranges. Therefore, when the phase of the unimorph near the resonance point is checked and if it exhibits inducitivity, the sensor face is unloaded. On the other hand, if it is capacitive, it becomes clear that a load is applied to the sensor face; i.e. the existence of powder can be detected (Figure 7).

Driving Circuit of the TSP series piezoelectric powder level Sensors

The TSP Series sensors incorporate TDK's custom-designed IC integrating a frequency sweep oscillation circuit, waveform shaping circuit, phase detection circuit, digital processing circuit, etc., and realize stable driving and detection performance.

This IC performs sweeping in the frequency range of 4 to 8kHz centering around 6kHz, which is the resonance frequency of the unimorph, and determines whether the input signal from the unimorph is inductive or capacitive. It outputs two values of High or Low, providing notification that no load is applied to the sensor if inducitivity is detected during the first sweeping or that load is applied to the sensor if no inductivity is detected.

![Figure 5 Supporting method and peripheral support structure of the piezoelectric unimorph [Piezoelectric unimorph holding method]](/system/files/pov_powder-leve-sensors_tec00005_de.png)

![Figure 5 Supporting method and peripheral support structure of the piezoelectric unimorph [Peripheral support structure]](/system/files/pov_powder-leve-sensors_tec00006_de.png)

![Figure 6 Equivalent circuit and impedance-frequency characteristic of a piezoelectric unimorph [Equivalent circuit]](/system/files/pov_powder-leve-sensors_tec00007_de.png)

![Figure 6 Equivalent circuit and impedance-frequency characteristic of a piezoelectric unimorph [Impedance-frequency characteristic]](/system/files/pov_powder-leve-sensors_tec00008_de.png)

![Figure 7. Changes of the powder amount and phase property [No load]](/system/files/pov_powder-leve-sensors_tec00010_de.png)

![Figure 7. Changes of the powder amount and phase property [Load applied]](/system/files/pov_powder-leve-sensors_tec00011_de.png)

![Figure 7. Changes of the powder amount and phase property [Load large]](/system/files/pov_powder-leve-sensors_tec00012_de.png)