Solution Guides

With the increasing speed and wave frequency in electronics, further reduction of ESL (equivalent series inductance) is required for capacitors, or 3-terminal feed-through filters must be used for noise filtering or decoupling. Furthermore, the need for low-ESL type products is increasing in electrical systems of automobiles in order to improve safety and comfort, and to support infotainment systems. Through a series of articles, we will introduce various solutions for automobile electronics using TDK's advanced low-ESL components.

Overview: use of 3-terminal feed-through filters to suppress noise from power lines in automotive electronics

More and more automotive electrical systems are equipped with in-vehicle camera systems integrated with image recognition technologies or millimeter wave radars for safety-related purposes such as collision avoidance systems, lane assist systems, and pedestrian detection systems, in addition to traditional basic functions of "driving, turning, and stopping." Automotive electronics that support these advanced driver assistance systems (ADAS) are required to process a large amount of data at a high speed, and therefore noise that occurs in them has higher frequencies.

Moreover, in recent years, noise suppression under relatively large currents (over 5A) is required in power lines of automotive electronics. Conventionally, filter circuits combining multiple elements, such as capacitors, inductors, or chip beads, have been used for EMC countermeasures in large-current power lines. TDK's YFF-A series of automotive 3-terminal feed-through filters consists of EMC countermeasure components featuring high reliability and support for high current, developed specially for automotive electronics through optimization of material and design. Components in the series are compact and have a good attenuation characteristic over a broad frequency range. Thus, a single element is capable of achieving a noise suppression effect equivalent to that of a filter circuit using multiple elements.

Fig. 1: Configuration of ADAS (image)

Characteristics required of EMC countermeasure components in power lines of automotive electronics

Why a low-ESL characteristic is required

A capacitor is the most basic electronic component for noise suppression in the power lines of electronics. A capacitor has a characteristic by which the higher the wave frequency, the easier current passes through it, and when a power line is connected to the ground through a capacitor, high-frequency noise is bypassed to the ground and separated.

The ideal capacitor is an element with capacitance (C) only. However, in reality, it has a resistive component (R) and inductance (L) due to terminals and internal electrodes. These are called “equivalent series resistance” (ESR) and “equivalent series inductance” (ESL). Because of its own capacitance and ESL, a capacitor operates as an LC resonance circuit. The frequency at which this phenomenon occurs is called the self-resonant frequency (SRF). The impedance of the capacitor switches from a reduction to an increase at this frequency, and the impedance-frequency characteristic of the capacitor draws a V-shaped curve. In other words, the impedance of a capacitor is a capacitive region determined by the capacitance until the SRF. However, it becomes an inductive region determined by the ESL after the SRF, and the action as an inductor becomes dominant.

Therefore, capacitors for reducing high-frequency noise must have a low ESR and ESL, as well as a higher SRF. As was previously described, the ESR and ESL are caused by the resistance and inductance of terminal electrodes and internal electrodes. Therefore, a reverse geometry capacitor, in which a low ESL is achieved by reversing the longitudinal direction and width direction of the terminal electrodes of a normal 2-terminal multilayer ceramic chip capacitor (MLCC) to make the current route wider and shorter, is also effective as a noise countermeasure.

TDK's YFF-A series 3-terminal feed-through filters have achieved even lower ESR and ESL values than those of 2-terminal MLCCs. Fig. 2 is a comparison of the impedance-frequency characteristics and ESL values of TDK's 2-terminal MLCC, reverse geometry capacitor and 3-terminal feed-through filter.

Fig. 2: Comparison of the impedance-frequency characteristics of TDK's representative low-ESL products

AEC-Q200-compliant high-durability 3-terminal feed-through filters

TDK's YFF-A series of automotive 3-terminal feed-through filters are AEC-Q200-compliant products, having high durability against high-temperature/high-humidity environments and thermal shock. Table 1 is an example of a comparison of the required test conditions for consumer products and automotive products. The YFF-A series of automotive 3-terminal feed-through filters was developed through optimization of material and design, by utilizing technologies and know-how accumulated through the development of 2-terminal products. It has satisfied the test conditions required to comply with AEC-Q200, which are much stricter than those for consumer products.

Table 1 Example of a comparison between the required test conditions for consumer products and automotive products

| Consumer applications | Automotive applications | |

|---|---|---|

| Temperature cycle test | -55〜85℃ / 5cycles | -55〜125℃ / 1,000cycles |

| Moisture load test | 40℃ / 90〜95%RH / 500h | 85℃ / 85%RH / 1,000h |

| High temperature load test | 85℃ / 1,000h | 125℃ / 1,000h |

Structure and principle of a 3-terminal feed-through filter

Internal electrode structure that achieves an excellent low-ESL characteristic

A slightly more detailed explanation of the structure and principle of a 3-terminal feed-through filter is provided below. Fig. 3 provides conceptual diagrams of the appearance, an equivalent circuit, and the internal structure of a 3-terminal feed-through filter. Although it is generally called “3-terminal”, it is actually composed of two terminal electrodes and two ground electrodes. It has an internal structure in which internal electrodes for conduction and internal electrodes for grounding are alternately layered.

Fig. 3: Appearance, equivalent circuit, and internal structure of a 3-terminal feed-through filter

Fig. 4 illustrates the flow of noise current in a 3-terminal feed-through filter connected to a power line. The noise current that enters the internal electrodes for conduction from the power line is bypassed to the ground through the internal electrodes for grounding. Because of the feed-through structure, the distance between the capacitor and ground is short, reducing the ESL. In addition, due to the parallel effect of the two ground terminals, the ESL becomes even smaller and the noise suppression effect is significantly enhanced.

Fig. 4: Mounting of a 3-terminal feed-through filter on a power line and the flow of a noise current

EMC solution using 3-terminal feed-through filters in power lines for automotive electronics

Solution: countermeasure against harmonic noise accompanying high-speed switching

The effectiveness of TDK's YFF-A series 3-terminal filters as a noise countermeasure in the power lines of automotive electronics is evaluated below.

A DC-DC converter is the most common power line for automotive electronics. It uses the switching method, in which direct current is broken into pulses and then converted into voltage. These pulses are made up of sine waves having the same frequency as the switching frequency and harmonics having frequencies equal to integer times of the switching frequency. Therefore, if no countermeasure is implemented, high-order harmonics will cause noise.

The harmonic noise suppression effect of the 3-terminal feed-through filter was examined using an evaluation circuit (Fig. 5) that uses a CMOS inverter (NOT gate). The harmonics generated by pulses with a switching frequency of 40MHz sent into the CMOS inverter were examined when a 2-terminal MLCC was installed in the power line and when a 3-terminal feed-through filter was install in the power line. The voltage wave form measured at the input line and the noise spectrum obtained by Fourier transform of spectrum analyzer data are shown below. Where the 2-terminal MLCC was used, harmonic noise with frequencies equal to integer times of the switching frequency can easily be observed. On the other hand, where the 3-terminal feed-through filter was used, harmonic noise was significantly suppressed.

Fig. 5: Harmonic noise suppression effect of a 3-terminal feed-through filter

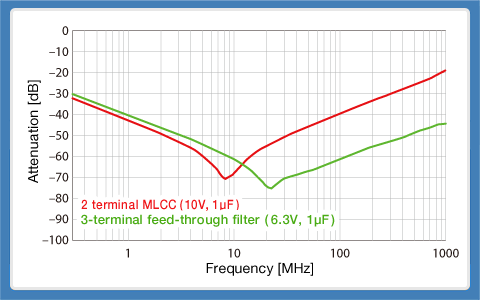

Fig. 6, which compares attenuation-frequency characteristics, also shows that the 3-terminal feed-through filter has an excellent attenuation characteristic at high-frequency regions over approximately 20 MHz.

Fig. 6: Comparison of attenuation characteristics

between 2 terminal MLCC and 3 terminal feed through filter

The basic concept of EMC countermeasures is to cut off noise from its source. TDK's YFF-A series 3-terminal feed-through filters are EMC countermeasure components featuring high reliability and support for high current, developed specially for automotive electronics. Since they exhibit a good attenuation characteristic over a broad frequency range due to an excellent low-ESL characteristic while being compact, they are optimal for high-frequency noise suppression in power lines for automotive electronics. They exhibit outstanding performance for the realization of comfortable car connectivity or autonomous driving systems.

<Major advantages, applications, and electrical characteristics of the YFF-A series automotive 3-terminal feed-through filters>

[Major advantages]

- Compact and high-performance EMC countermeasure components specialized for automotive applications. Also demonstrate an excellent effect for decoupling use.

- Compliant with AEC-Q200

- Realize a good noise attenuation characteristic over a broad frequency range

- Support large current (6 to 10 A)

- Reduce the number of components, mounting cost, and mounting space, and simplify the PCB layout.

[Major uses]

- EMC countermeasure and decoupling in power lines for various automotive electronics such as ECUs, car navigation systems, in-vehicle camera systems, millimeter wave radar systems, etc.

[Product lineup and main electrical characteristics]

[YFF-A series automotive 3-terminal feed-through filters] Product information and sample purchase

* Please select the type/product code suited to your use, and use it to improve the reliability of your product.

![[Product lineup and main electrical characteristics]](/system/files/sog_3tf_low-esl1_3tf01-007_de.png)