Latest filters combine miniaturization and high performance

Figure 1: Configuration of a typical in-vehicle LAN

EMC component prevents malfunctions of electrical devices

ECUs are used in various parts of the car: body systems, safety systems, powertrain systems, and multimedia/data communication systems. Information obtained by sensors or actuators is shared among these ECUs through a gateway, and this data helps to maintain safe comfortable and energy efficient operation. In the early days, automobile electronic devices were connected to the control unit on a one-on-one basis and controlled individually. So the number of wiring harnesses increased with each additional function, hindering manufacturers’ attempts to reduce the weight of vehicles. In-vehicle LAN technologies, such as CAN (controller area network), were developed to solve this issue. The adoption of in-vehicle LANs has led to a reduction in the number of wiring harnesses, as well as supporting the implementation of advanced functions, by providing a networked connection between electrical devices.

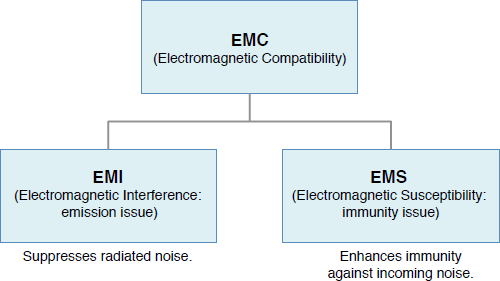

Figure 2: Emission issue and immunity issue

An EMC measure realizes both EMI measures (noise generation countermeasures) and

EMS measures (incoming noise counter-measures).

An automobile is a source of various types of noise, including radiated noise from the spark plug and surge noise from the motor and alternator. In order to prevent electrical devices from malfunctioning, it is necessary to adopt EMI measures (emission measures) to suppress radiated noise, and EMS measures (immunity measures) to enhance a device’s immunity against incoming noise. The term ‘EMC measures’ refers to the simultaneous implementation of both these types of measures.

Cables connecting ECUs function as antennas that radiate or pick up noise. Although there are various types of automobile EMC components, the most reliable and effective measure in a high-speed CAN or FlexRay in-vehicle LAN using the differential transmission method is to attach a common mode filter to each of the network’s nodes.

TDK offers common mode filters for in-vehicle LANs in a wire-wound troidal core type and wire-wound drum core type, to which a plate core is attached. The drum core type is smaller than the troidal core type. Nowadays, however, with the development of functions for automotive electronic control systems, many common mode filters may be mounted on one circuit board: this calls for even smaller components than before. The ACT1210 type has been developed in order to respond to this market need.

Unique structure and new ferrite material result in size reduction

TDK's new ACT1210 type consists of 3225 size (3.2 x 2.5 mm) common mode filters, featuring an approximately 44% smaller mounting area and approximately 50% lower volume than the existing 4532 size (4.5 x 3.2 mm) ACT45B series. On its own, simply reducing the device’s size would impair the common mode filter’s characteristics. Therefore, in order to achieve both size reduction and high performance simultaneously, TDK has adopted a new technology for the structure and a new material (Fig. 3).

Figure 3: TDK's solution that has achieved size reduction and low resistance

The unique new structure was developed to provide the new common mode filters with low magnetic resistance. Magnetic resistance corresponds to the electrical resistance in an electrical circuit, and expresses the difficulty for magnetic flux to pass through a magnetic circuit (magnetic path). The magnetic resistance is proportional to the square of the number of turns of the coil, and is inversely proportional to the inductance. In other words, the larger the coil inductance (L), the smaller the magnetic resistance (Rm). However, in drum-type common mode filters, the contact area between the drum core and the plate core in general becomes smaller when their size is reduced, which in turn reduces the inductance and increases the magnetic resistance.

TDK focused on the position of the wire connection parts, in order to increase the contact area between the drum core and plate core. In the existing products, the wire connection parts were located between the plate core and drum core. By moving them to the bottom of the drum core, the contact area was increased, and thus the size of the device could be reduced while maintaining low resistance.

In addition, the magnetic resistance is inversely proportional to the permeability of the ferrite core material. In other words, the larger the permeability (μ), the smaller the magnetic resistance. TDK has developed a new ferrite material with higher permeability through the use of advanced material technologies, and achieved low magnetic resistance by this means as well as through the implementation of an ingenious structure.

Summary

The radiated noise test (CISPR25-Class5) data for the ACT1210 type is shown in Fig. 4. Use of the ACT series suppresses radiated noise to a level below the maximum permitted value (QP value). Fig. 5 shows the data from a BCI test which evaluates the immunity of the ACT1210 type when strong electromagnetic noise is induced in a harness connected to an automotive electrical device. This data also indicates stable characteristics.

Figure 4: Radiation noise (emission) test of ACT1210 type

Figure 5: Effects of ACT1210 type in a BCI (immunity) test

With the development of telematics, and the adoption of new wireless connectivity technologies in the car, EMC measures will become increasingly important. Moreover, automobile electronic components used under severe conditions require characteristics such as vibration resistance, shock resistance or thermal resistance that are far better than those of general purpose electronic components. TDK's ACT1210 type common mode filters for in-vehicle LANs also feature high stability and reliability, owing to the introduction of an advanced automatic wire winding system as well as other technologies.

Main features, applications and specifications of ACT1210 type

Main features

- Reduced size and low magnetic resistance (high common mode inductance) owing to a unique core structure, new ferrite material, high-precision automatic wire winding system, etc.

- Supports a wide range of operating temperatures (-55 to +150°C) including the severe environment found in the engine bay

- Features excellent thermal resistance through the use of wire with high heat resistance, as well as high stability and reliability owing to the use of a high precision automatic wire winding system

Main applications

- Common mode filters for in-vehicle LAN systems, including CAN and FlexRay networks

Main electrical characteristics

| Product name | Common mode impedance at 10MHz[Ω]min. |

Common mode inductance at 100kHz[μH]+50/30% |

DC resistance [Ω]max. |

Rated current DC[A]max. |

|---|---|---|---|---|

| ACT1210-110 | 300 | 11 | 0.4 | 0.30 |

| ACT1210-220 | 500 | 22 | 0.5 | 0.25 |

| ACT1210-510 | 1000 | 51 | 0.7 | 0.20 |

| ACT1210-101 | 2200 | 100 | 1.5 | 0.15 |