Application Note How to use PTC limit temperature sensors

PTC thermistors have the property that their resistance rises significantly when a certain temperature is exceeded. This property makes them suitable for use as temperature protection devices that detect defined high temperatures to protect circuits from overheating.

TDK offers various types of PTC limit temperature sensors and motor protection sensors that incorporate PTC thermistors and serve as temperature protection devices. This article describes typical applications of such sensors.

Advantages of PTC limit temperature sensors

PTC thermistors are temperature-dependent resistors based on special semiconductor ceramics with a high positive temperature coefficient (PTC). They exhibit relatively low resistance values at room temperature, but their resistance rises significantly when they are heated by an external heat source to above a certain temperature (Curie temperature).

With this unique property PTC thermistors are used to protect components and devices from overheating.TDK's broad portfolio of high-quality and highly reliable PTC limit temperature sensors includes SMD, leaded disk and screw-on types, so that a suitable component is available for nearly every overtemperature detection requirement. Motor protection sensors are PTC limit temperature sensors with a special designed shape, allowing them to be directly assembled within the windings (stator side) of electric motors.

The following are applications for PTC limit temperature sensors and motor protection sensors.

* In the following articles and diagrams PTC limit temperature sensors and motor protection sensors are referred to as PTC thermistors for short. Also, circuit diagrams are simplified.

Applications of PTC limit temperature sensors

Application: Overtemperature protection for transistor circuits

PTC limit temperature sensors can be used as a simple and convenient way to protect transistor circuits from a rise in the ambient temperature or from heat generated by the transistor itself.

With transistor amplifier circuits like the one shown in the following diagram, temperatures higher than the rated temperature may degrade the characteristics of transistors.

A PTC thermistor used in such circuits detects a rise in the ambient temperature and enters a high ohmic state. As a result, the base-emitter voltage of the transistor drops and the transistor cuts-off the load current. When the ambient temperature returns to the normal level, the PTC thermistor returns to its original low resistance state.

Figure 1 Overtemperature protection for transistor circuits

Application: Overtemperature protection for power semiconductor devices

The diagram below is an example of an overtemperature protection circuit, in which a PTC thermistor is thermally bonded to a heatsink (radiator). When a certain temperature is exceeded, the resistance of the PTC thermistor rises significantly and the base voltage of the power transistor drops. As a result, the collector current decreases and heat generation is suppressed, thereby protecting the power transistor from overheating.

Figure 2 Overtemperature protection for power semiconductor devices

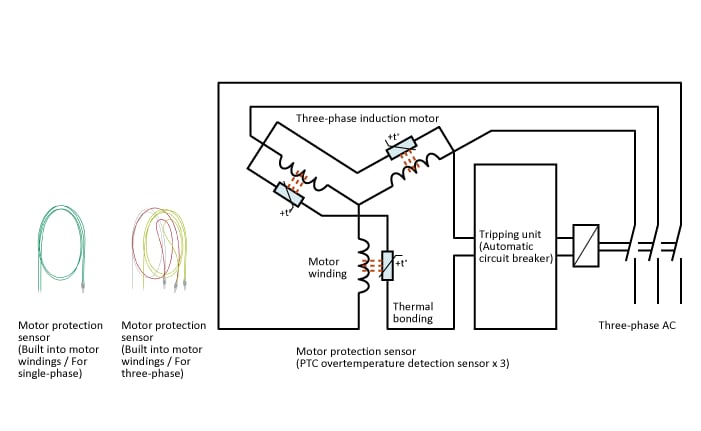

Application: Overtemperature protection for single-phase/three-phase induction motors

Single-phase and three-phase induction motors, which are used in many electronic devices including industrial equipment, incorporate protection devices against overcurrent and overheating. In particular, PTC thermistors are used as motor protection sensors to protect the motors from overheating. Highly reliable protection can be realized by thermally bonding three motor protection sensors to a winding of a motor (stator side) as shown in the diagram below. When the PTC thermistor heats up to a certain temperature, a tripping unit (automatic circuit breaker) is activated to shut off the power supply.

Figure 3 Overtemperature protection for three-phase induction motors

Related pages

■ PTC Limit Temperature Sensors Product Portals