Product Overview MEMS Microphone T4064/T4081

MEMS microphone with wide range of application from recording to sound event detection

In recent years, for devices such as smartphones, MEMS microphones in which MEMS (Micro Electro Mechanical System) technology is utilized have been increasingly adopted. Further downsizing and acoustic characteristics improvement of MEMS microphone is required in electrical devices with the features of sound event detection or recording such as wearable products, action cameras, digital cameras, as well as smartphones. Also, high-performance microphone is a must in utilizing speech recognition interfaces. To respond to these needs, TDK has successfully achieved further downsizing/low profiling/high performance, based on the CSMP (Chip Size MEMS Packaging) technology cultivated thorough the development of SAW device, etc.

MEMS microphone is a compact microphone package in which MEMS chip, an acoustic sensor (acoustic transducer), and IC chip for signal processing are assembled. The MEMS chip is formed into a chip by forming a microstructure on a silicon wafer using the techniques of photolithography, etching, etc., applying semiconductor manufacturing technology. It is only several millimeters in size, and about three pieces of MEMS microphones are mounted in one smartphone. MEMS microphones are also used for a microphone with earphones for hands-free calls, headphones with noise canceling functions, and so on.

2nd-generation package adopting metal cap excellent in reliability and durability

For T4064 and T4081, a new packaging that belongs to the TDK's 2nd-generation MEMS microphone is adopted. Figure 2 shows the overview of the internal structure. The microphone element MEMS chip and the signal processing ASIC are mounted on a ceramic substrate, sealed with a polymer foil, and covered with a cap. In these products, T4064 and T4081, a metal cap is employed instead of the conventional resin cap.

The MEMS microphone is connected to the external environment through the sound hole. A diaphragm (vibrating electrode plate) and a back plate (fixed electrode plate) are arranged with a small gap between the sound hole and the back chamber (cavity) of the MEMS chip.

The diaphragm and the back plate behave like a parallel plate type capacitor, and when the diaphragm vibrates due to the sound pressure, the gap length between the back plate and the capacitance changes. The MEMS microphone is a microphone called "capacitance type" that extracts these changes as electrical signals.

Figure 3 shows the MEMS microphone's circuit in block diagram image. The charge pump is a booster circuit that supplies the back plate with bias voltage, and sensor signals are sent to the preamplifier for the processes such as amplification and others, and then output.

T4064 that achieves both further downsizing and acoustic characteristics improvement

TDK MEMS microphone T4064 features its extremely small size of 2.7 x 1.6 x 0.89mm (L x W x H) and low-profiling, which achieved further improvement of the acoustic characteristics while reducing the mounting area by approximately 15% compared with T4063 type, the smallest product among the conventional models. It is optimized for the applications such as smartphones, microphones with earphones, headsets, etc.

Microphones' main acoustic characteristics include sensitivity, dynamic range, and frequency characteristics, etc.

The sensitivity of microphones is indicated by the magnitude of the output voltage when a specific sound pressure is applied. For a MEMS microphone, the higher the displacement of the diaphragm is, the more sensitive the microphone is for the same sound pressure. Generally, therefore, when MEMS microphone is downsized, the area of diaphragm tends to get smaller, which reduces the sensitivity.

However, the sensitivity of MEMS microphone involves not only the area of diaphragm, but also its material, thickness, internal stress, and the distance from the back plate, etc. TDK's MEMS microphone T4064 has extremely flat frequency characteristics and it covers from low frequency to ultrasonic wave, so it can be applied as measurement application.

T4081, the clipping-free microphone even at a loud sound of jet engine class

Also, TDK MEMS microphone T4081 (3.35 x 2.5 x 0.95mm) features high input durability, with which does not cause clipping even at loud volume as high as 130dB.

Dynamic range is the ratio expressed in dB, between the levels of detected maximum and the minimum sound pressure that the microphone can pick up. Microphones are required to have as high sensitivity and wide dynamic range as possible. However, the sensitivity and dynamic range are in the relationship of trade-off.

In MEMS microphone, if the sensitivity is raised in order to pick up small sounds, the displacement of diaphragm increases and the allowable sound pressure level is reduced, which results in narrower dynamic range. Due to this fact, when a loud sound is picked up, the output signal distortion is increased, which causes clipping.

Conversely, if the amount of diaphragm displacement is suppressed so as to reduce distortion at high volume, the allowable sound pressure level will be high and the dynamic range will be wide, but the sensitivity is decreased.

The degree of output signal distortion is generally expressed in THD (Total Harmonic Distortion).

Figure 4 shows the THD-SPL (sound pressure level) of the new products T4064 and T4081. THD-SPL characteristics are generally expressed in the maximum SPL up to the point at which THD exceeds 1%. T4064 maintains the THD of 1% or less until reaching 110dB. 110dB is a level of sound heard at places like under a girder bridge when a train passes, which makes you feel very noisy. T4064 has the characteristics that can pick up sounds without clipping even at high volume of this level.

As the graph shows, the THD-SPL characteristics of T4081 are amazing, reaching 130dB. This is the level of sound emitted by a jet engine in a close range, a roaring sound that feels physical pain. It means T4081 is able to pick up the loud sound like a live rock concert without clipping.

What made this amazing acoustic characteristic possible is that we adopted innovative design, double-back plate for the acoustic sensor part of T4081 MEMS chip.

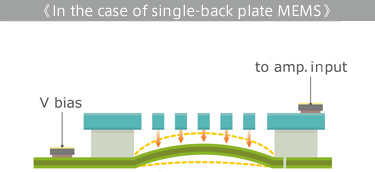

Figure 5 shows the structure of a general single-back plate, and the structure of a double-back plate, which was adopted for T4081. The single back plate is an asymmetrical structure in which one back plate faces the diaphragm. On the other hand, the double-back plate is a symmetrical structure in which two pieces of back plates are arranged face-to-face on the both sides of diaphragm.

As shown in Figure 6, in the single-back plate, the diaphragm is displaced to one side (back-plate side) by the electrostatic force (Coulomb force) of the bias voltage even in the state of zero-SPL where no sound pressure is applied. When sound pressure is applied from this state, the diaphragm is displaced asymmetrically, and the THD increases with the rise of sound pressure, which results in clipping.

Meanwhile, in the double-back plate, the diaphragm shows no displacement because the electrostatic force acts on the both sides of the diaphragm evenly in the state of zero-SPL where no sound pressure is applied. In addition, since the diaphragm is displaced symmetrically even when the sound pressure is applied, it has superior THD-SPL characteristics, which shows high input durability allowing no clippings. The THD-SPL characteristics and high S/N ratio (66dB(A)) make it possible to carry out recordings with good quality even for remote sound source.

The diaphragm is displaced to one side by the electrostatic force of the bias voltage (↓) even in the state of zero-SPL where no sound pressure is applied.

When sound pressure is applied in this state, the diaphragm is displaced asymmetrically, and the THD increases, which results in clipping.

In the state of zero-SPL where no sound pressure is applied, the diaphragm shows no displacement because the electrostatic force of the bias voltage (↓↑) acts on the both sides of the diaphragm evenly.

Even if high volume is applied in this state, since the diaphragm is displaced symmetrically, THD is suppressed and the clipping hardly occurs.

TDK MEMS microphone T4081 is ideal for high-end smartphones, earphones or headset with ANC (Active Noise Cancelling) function, and so on. ANC is a function in which the processing circuit generates an anti-phase signals to the noise sampled from the surrounding noises by the microphone, and cancels the noises using those generated anti-phase signals.

T4081 has high S/N ratio, and its high input durability, small size make it possible for T4081 to be compactly stored in ear cup modules of headphones, etc. with speakers and an ANC circuit. Equivalent noise (self-noise) level is as low as 30dB or less, and it can be used with low output in a usual usage, which leads to battery saving. In addition, since the maximum SPL is as high as 130dB, clipping does not occur even if the output is raised under the noise environment.

TDK MEMS Microphone T4064/T4081 Main Specifications and Electrical Characteristics

TDK MEMS microphones T4064/T4081 are products made with technologies of MEMS and packaging cultivated through the manufacturing of SAW devices and other products. Among the product lineup, T4064 introduced in this article belongs to the industry's smallest class products, and T4081 has high input durability; you can select from these in accordance with your applications.

| Type | T4064 (Smallest among TDK products) |

T4081 (High input durability product) |

|---|---|---|

| Part No. | MMIC271609T4064 | MMIC332509T4081 |

| Dimensions | 2.7 x 1.6 x 0.89mm | 3.35 x 2.5 x 0.95mm |

| S/N ratio | 61.5dB(A) (20 to 20kHz) |

66dB(A)(20 to 20kHz) |

| THD 1% | 110dB SPL | 130dB SPL |