Humidity Sensors CHS Series

Electronic polymer humidity sensors

Among polymer humidity sensors, there are expandable types and electronic types. Among the electronic types, there are variable resistance types and variable capacitance types (Figure 1). The advantages and disadvantages of each type are described in the following, while comparing the structure and detection principle of each electronic type.

Structure and principle of an electronic polymer humidity sensor

In a variable resistance humidity sensor, the resistance of the sensor element changes in response to humidity changes, and the resistance changes are extracted as electrical signals.

The basic structure of a variable resistance humidity sensor is shown in Figure 2. A noble metal thick film conductor such as gold or ruthenium oxide is printed in a comb shape on an alumina substrate, and it is fired to form electrodes. Next, a polymer material is applied on these electrodes to form a humidity sensing film.

The "humidity sensing" mechanism of the polymer film can be explained by the existence of movable ions that are enabled to move freely through the absorption of water molecules. Namely, it is believed that it treats impedance changes caused by the changes in the number of movable ions as electrical conduction. In contrast, a variable capacitance humidity sensor utilizes the characteristic in which the capacitance of the sensor element changes in response to humidity changes, and the capacitance changes are extracted as electrical signals. Figure 3 shows the basic structure of a variable capacitance humidity sensor. The bottom electrode, such as Au-Pt, is formed on an alumina substrate, and a polymer humidity sensing film, such as cellulose or PVA, is evenly applied on it with a thickness of several μm. The top electrode is formed on top of it by applying Au thin film, etc. In other words, a variable capacitance humidity sensor is a capacitor that uses a polymer film as a dielectric.

Characteristics of the Capacitance Variable Type Sensors and Resistance Variable Type Sensors

A capacitance variable humidity sensor element features excellent linearity, and is capable of measuring from a relative humidity of 0% RH.

On the other hand, however, it features a large capacitance of several hundreds pF at 0% RH, and a small variation range of several tens pF in the range from 0 to 100% RH, and it therefore becomes necessary to increase the small capacitance variation and simultaneously compensate a large zero offset. For this reason, it has disadvantages such making circuits highly complex and expensive and requiring regular calibration.

On the contrary, a variable resistance humidity sensor element has disadvantages such as difficulty in performing measurement in the low humidity range (5% RH or lower), difficulty in securing a dynamic range in circuits because the impedance variation range exhibits an exponential characteristic reaching four to five digits, and large property fluctuations due to temperature (Figure 4).

Overall Superiority of Variable Resistance Type Sensors

However, for variable resistance humidity sensors, their impedance variation range or temperature characteristics can be overcome or solved through improvements of circuit technologies, and it is possible to fully utilize their advantage of being easy to use and inexpensive. In addition, with regard to their problem of becoming insensitive in a low humidity range, the need for the offset adjustment can be eliminated by discarding measurements in the humidity range of 5% RH or lower, which also eliminates aging due to offset changes and thus makes periodic calibration work unnecessary. Thus, this disadvantage can be turned into a large advantage in practical applications.

Based on the above considerations, TDK has adopted the variable resistance type for its humidity sensors. TDK has realized units that maximize the above-described advantage of variable resistance humidity sensors through its proprietary polymer material and circuit design technologies, and these are widely used in various fields including consumer appliances, office equipment, and measuring instruments.

Signal Processing Circuit of the CHS Series

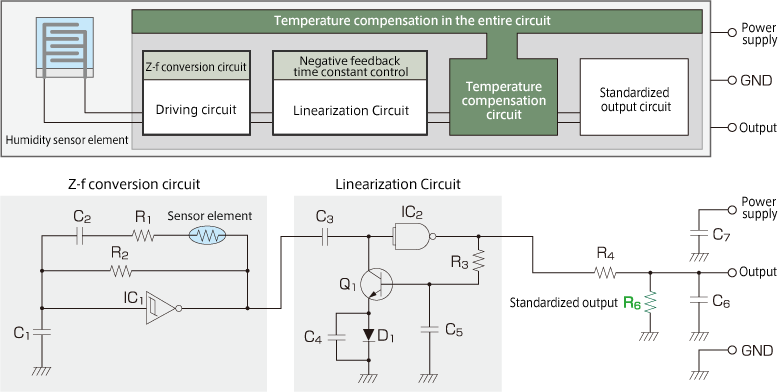

The following describes the signal processing circuit of the CHS Series humidity sensor units of TDK, based on the circuit block diagram and circuit schematic in Figure 5.

Driving Circuit

In order to avoid electrolysis (polarization), AC voltage is applied to the humidity sensor element through capacitor C2 that cuts DC components. When doing so, a frequency between 200Hz and 10kHz is usually selected. This is because capacitive impedance at a high humidity will become unignorable at 200Hz or lower frequencies and, by contrast, impedance at a low humidity will become too low at 10kHz or higher frequencies.

However, in low humidity and high humidity ranges, impedance variation is not completely exponential, but the variation range becomes smaller. For this reason, it is not possible to achieve output with good linearity by logarithmically compressing the intrinsic characteristics of the sensor element; therefore, in actual sensors, linearization is performed by providing several humidity ranges and using a different compression rate in each range.

In the driving circuit of the CHS Series sensor units, a Z-f conversion circuit that changes the driving frequency with the impedance of the humidity sensor element itself. In other words, the driving frequency is decreased in the low humidity range to increase the impedance, and the driving frequency is increased in the high humidity range to decrease the impedance, so that the characteristic curve becomes exponential-like and can be easily linearized when logarithmically compressed.

Linearization Circuit

It has been previously described that a variable resistance humidity sensor requires logarithmic compression because impedance variations in response to humidity become exponential. Normally, this logarithmic compression is performed by a log amplifier.

In the CHS Series humidity sensor units, a frequency that changes according to the humidity obtained by the Z-f conversion circuit is converted into a pulse wave with the pulse width τ. When doing so, control of the negative feedback time constant is performed using a nonlinear element to make the pulse width τ large at low humidity or small at high humidity. As a result, the exponential characteristic as shown in the graph of Figure 6 (left) is logarithmically compressed and becomes an output voltage characteristic as described in the graph of Figure 6 (right).

Temperature Compensation Circuit

When the characteristics of the variable capacitance type and variable resistant type sensors were described, two graphs showing the impedance-temperature characteristic of a humidity sensing element were presented (Figure 4). As the characteristic lines in the "by temperature" graph indicate, the impedance value of a humidity sensor element shows a twofold to threefold change when temperature changes by 20 to 30°C. Since the impedance-temperature characteristic of an NTC thermistor is two times or less, it is not possible to perform temperature compensation of a humidity sensor using a thermistor alone.

Therefore, in the CHS Series, temperature compensation of the humidity sensor elements is performed by identifying the temperature characteristics of all the semiconductor elements used for the driving circuit, linearization circuit, etc., and making comprehensive use of them. As a matter of course, it is an absolute requirement to that end to integrate the humidity sensor element and signal processing circuit, as well as to make their temperatures the same*.

*Since thermal equilibrium is a very important factor when measuring humidity, it becomes difficult to integrate the detection element and circuit if the signal processing circuit generates a large amount of heat. TDK has cleared this issue by adopting C-MOS IC, which keeps the maximum current consumption under 0.5mA and significantly suppresses heat generation in the signal processing circuit.

In addition, it is possible to use an NTC thermistor as an auxiliary temperature compensation element. This will achieve stable performance in even broader temperature range.

Standardized Output Circuit

In the CHS Series humidity sensor units, circuits are standardized so that output at 100% RH becomes Edc 1V, in order that output can be easily read directly.

Sensing Property and Output Characteristic of the CHS Series

By using these signal processing circuits, temperature and linearity characteristics, which have been considered to be the drawbacks of conventional variable resistance humidity sensors, have been significantly improved and an output precision and stability equivalent to those of variable capacitance humidity sensors have been achieved. The CHS Series sensors achieve a flat sensing property over a broad range, while using variable resistance humidity sensor elements that have an impedance-temperature change rate larger than that of an NTC thermistor. In addition, sensitivity deterioration due to environmental factors, etc., was also compressed by logarithmically compressing impedance changes with respect to humidity. As a result, excellent stability that maintains the initial characteristics for a long period of time has been achieved.

Advantages in Practical Applications

Since the signal processing circuits and sensor element are integrated, it is not necessary to remove the sensor element using a cable, which realizes accurate signal processing that is not affected by noise even when the impedance of the element becomes high at low humidity. In addition, since signals have already been processed into DC signals, it is possible to lay the cable over a long distance without using expensive shield cable (tested up to 150 meters; up to approximately 2km is theoretically possible).

Moreover, since the sensor element and signal processing circuits are integrated, the user is not required to perform adjustment of the circuits accompanying variations in the sensor elements or replacement of the elements. This is a large benefit in terms of ease of use.

![Figure 4 Fluctuation of impedance-humidity characteristic of a humidity sensing element [Impedance-humidity characteristic of a humidity sensing element (by frequency)]](/system/files/pov_numidity-sensors_tec00004_de.png)

![Figure 4 Fluctuation of impedance-humidity characteristic of a humidity sensing element [Impedance-humidity characteristic of a humidity sensing element (by temperature)]](/system/files/pov_numidity-sensors_tec00005_de.png)

![Figure 6 Logarithmic compression of the output voltage characteristic of the Z-f conversion circuit [Output voltage characteristic of the Z-f conversion circuit without/with logarithmic compression]](/system/files/pov_numidity-sensors_tec00006_de.png)