Power Supply Inductor for High Speed In-vehicle LAN

PoC (Power Over Coax) is where the signal line and the power line are carried over a single coaxial cable

With the aim of improving things like safe driving, lowering the environmental burden, and increasing comfort, automobiles have continued evolving without stopping. In in-vehicle electronics too, car navigation systems and car audio have always required this from the beginning, but recently the proliferation of sensors and camera equipment needed in order to implement IVI (In Vehicle Infotainment) Systems and ADAS (Advanced Driving Assistance System) has increased the need of a high speed in-vehicle LAN that connects multiple ECUs (Electronic Control Units) together.

So then, in this kind of advanced in-vehicle LAN for multimedia and information transmission, in-vehicle Ethernet (maximum transmission speed of 100Mbps) is used for two way transmissions, while LVDS (Low Voltage Differential Signaling) used by multiple electronic devices has been introduced for one way transmission such as sending video signals from cameras (rear view cameras, side view cameras, etc.). Moreover, in LVDS transmissions, in order to lightening the weight of wire harnesses, advances the implementation of PoC (Power over Coax) where one line carries both signal transmission and power supply.

The Role of Power Inductors in PoC

Not only in LVDS, in the existing data transmission formats in general use, the signal line (AC component) and power line (DC component) were sent using different lines. However, in the case of in-vehicle LANs, the weight of the wire harness has a direct effect on the fuel consumption. That is, in in-vehicle LAN for multimedia and information transmission, it is possible to deploy not only rear cameras, but multiple camera modules, in the side, front and so on, so by reducing the number of wires, there are clearly visible benefits in lightening the weight of the wire harness.

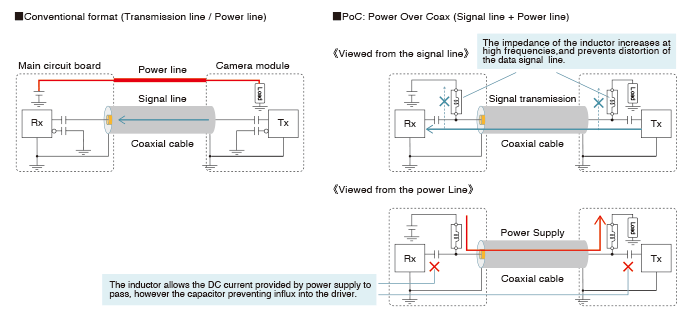

So then, the attention has been paid to systems where signal transmissions and power supply are sent in the same line. When a coaxial cable is used as the line, the system is called PoC (Power over Coax). An example of in-vehicle camera system that uses coaxial cable is shown in Figure 1. In the conventional format, the power line and the signal line are independent, but in the PoC format, one straight coaxial cable is connected to each power line of the main circuit board and of the camera modules. For this reason, in the PoC format, in order not to send a high frequency signal down a power line with low load impedance, there needs to be high impedance at junctions, and inductors are connected in series because the inductance of a inductor increases at high frequencies, preventing influx of signals. By contrast, in respect of the influx of the power line’s DC component to the driver side, this is prevented by connecting capacitors in series.

Figure 1: A comparison of conventional format and PoC and the roles of inductors and capacitors in PoC

Characteristics and composition required of an inductor for use with in-vehicle PoC

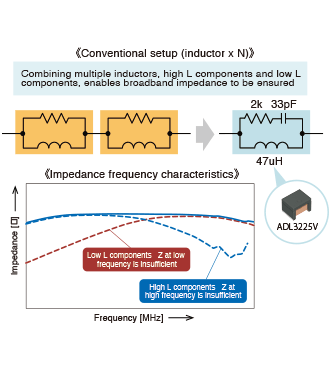

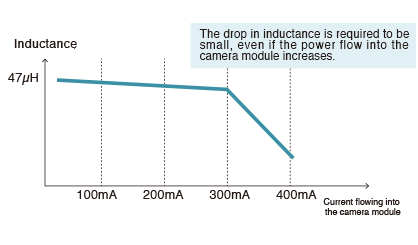

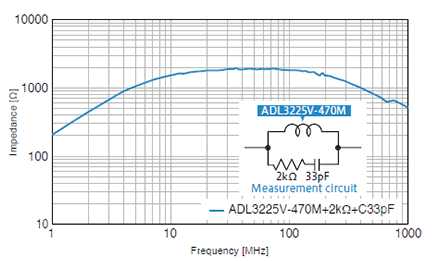

LVDS is unidirectional, as was said before, but although video signals are sent from the transmitter (Tx) to the receiver (Rx) in a single direction, the control signals (I2C) flow from the main circuit board to the camera modules, therefore strictly speaking, the signals flow in both directions. For that reason, inductors require high impedance in respect of both the video signals (maximum transmission speed 1.5 Gbps) and control signals (around several hundred kbps), and broadband characteristics between several hundred kbps and 1.5GHz are required. However, with conventional power inductors, the self- resonant frequency (SRF) where the impedance reaches a peak, is low, and as shown in Figure 2, because multiple high L (inductance) components and low L components are combined to achieve the broadband range, there is the problem that space saving is difficult. Also, because electric current of around 100mA flows through the power supply for the camera module, that current, in order not to magnetically saturate the inductor, is required to have DC superimposition characteristics (Figure 3).

The product that provides the solution to these required characteristics is the ADL3225V type that raises the self-resonant frequency, together with achieving the DC superimposition characteristics, by adopting the original coil design and construction different to that of conventional power inductor.

Figure 2: Conventional inductor structure for PoC

Figure 3: DC superimposition characteristics required of PoC inductors

Realizing Broadband Impedance Characteristics and Good DC Superimposition Characteristics

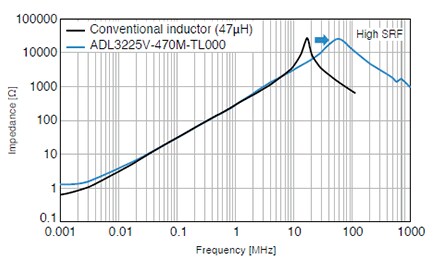

As shown in Figure 4, in comparison with conventional products (47μH), we can understand the shift of the self-resonant frequency (SRF) of the ADL3225V to the high frequency side. In addition, just a single unit of the Series can achieve high impedance in the broadband range that is equivalent to the impedance characteristics achieved by a conventional setup using multiple power supply inductors (Figure 5). In addition, as a result of the introduction of materials technology and new structures, it has also realized the outstanding DC superimposition characteristics (performance guaranteed temperature range from -40°C to 105°C) required by camera modules.

Figure 4: Self Resonant Frequency (SRF) Shifts to Higher Frequencies

Figure 5: impedance-frequency characteristics of ADL3225V

Summary

In order to use the high resolution of in-vehicle cameras for safe and comfortable driving, the adoption of PoC as the interface for an in-vehicle LAN capable of high speed transmission of large volumes of video image data has been making rapid progress. We brought ferrite technology, coil technology and design technology, which TDK have been using for many years, together to develop the ADL3255V series of inductors, which are designed for use in the overlapping power and signal lines used in high speed interfaces. By reducing the number of components, we realized the PoC that was able to ensure equivalent characteristics, while saving space. At TDK, we are going to make our product lineup of the electronic components and devices that support higher speed and higher precision of in-vehicle LAN, including common mode filters for various kinds of in-vehicle LAN standards such as CAN/FlexRay/Ethernet, even more substantial.

ADL3225V Series - The main features, uses and electronic characteristics

Appearance and Equivalent circuit

Appearance

Equivalent circuit

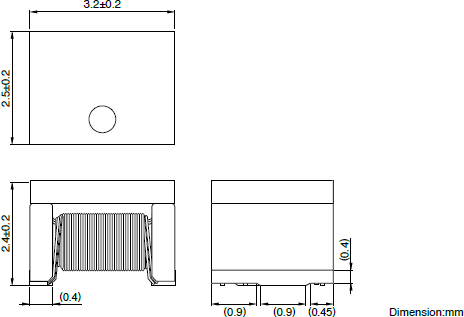

Shapes and dimensions

Main Features

- Small size and thin form factor (mounting area 3.2 x 2.5 mm, height 2.6mm max.)

- Achieving broadband impedance characteristics and good DC superimposition characteristics as the result of an original coiled wiring design and original structure

- Ensuring consistent high quality and reliability as the result of a completely automated manufacturing process

- Solder free design

- AEC-Q200 compliant

- Compliant with RoHS Directives on lead free solder

- Operating Temperature Range (Including Self-Temp. Rise) : -40 to 105°C

Main Uses

- Inductor for use with separate signal and power lines in in-vehicle PoC (Power Over Coax)

Series Lineup and Main Electronic Characteristics

| Part No. | Inductance @100kHz[μH] |

Inductance Tolerance [%] |

DC resistance Rdc max.[Ω] |

Rated Current 1 lsat typ.[mA] |

Rated Current 2 ltemp typ.[mA] |

|---|---|---|---|---|---|

| ADL3225V-470MT-TL000 | 47 | 20 | 0.9 | 300 | 500 |

Isat: Based on inductance variability (30% reduction of official figures)

Itemp: When based on temperature increase (Temperature rise of 40°C degrees from self-heating)

Other products for PoC (ADL3225VT Series) - The main features, uses and electronic characteristics

Appearance and Equivalent circuit

Appearance

Equivalent circuit

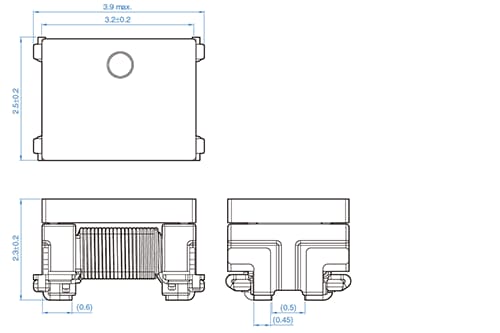

Shapes and dimensions

Main Features

- Small size and thin form factor (mounting area 3.2 x 2.5 mm, height 2.5mm max.)

- Achieving broadband impedance characteristics and good DC superimposition characteristics as the result of an original coiled wiring design and original structure

- Ensuring consistent high quality and reliability as the result of a completely automated manufacturing process

- Solder free design

- AEC-Q200 compliant

- Compliant with RoHS Directives on lead free solder

- Operating Temperature Range (Including Self-Temp. Rise) : -40 to 150°C

Main Uses

- Inductor for use with separate signal and power lines in in-vehicle PoC (Power Over Coax)

Series Lineup and Main Electronic Characteristics

| Part No. | Inductance @100kHz[μH] |

Inductance Tolerance [%] |

DC resistance Rdc max.[Ω] |

Rated Current 1 lsat typ.[mA] |

Rated Current 2 ltemp typ.[mA] |

|---|---|---|---|---|---|

| ADL3225VT-100M-TL000 | 10 | 20 | 0.15 | 450 | 1300 |

| ADL3225VT-4R7M-TL000 | 4.7 | 20 | 0.1 | 720 | 1500 |

Isat: Based on inductance variability (30% reduction of official figures)

Itemp: When based on temperature increase (Temperature rise of 40°C degrees from self-heating)

∗This article is based on our evaluation result.