Real-Time Intelligence at the Edge: edgeRX + edgeRX Vision for Predictive Maintenance and Machine Health Monitoring

edgeRX by TDK SensEI offers a comprehensive solution that streamlines real-time industrial machine health monitoring and predictive maintenance. By combining advanced sensors, a secure gateway, and powerful AI analytics, edgeRX continuously collects and analyzes machine data, providing instant, actionable alerts directly at the equipment. This enables engineers and plant managers to make faster, data-driven decisions, reduce unplanned downtime, and optimize maintenance strategies. With edgeRX, organizations can enhance operational efficiency and security without relying on expensive external experts, making it an ideal choice for modern industrial environments.

Industrial Machine Health Monitoring Overview

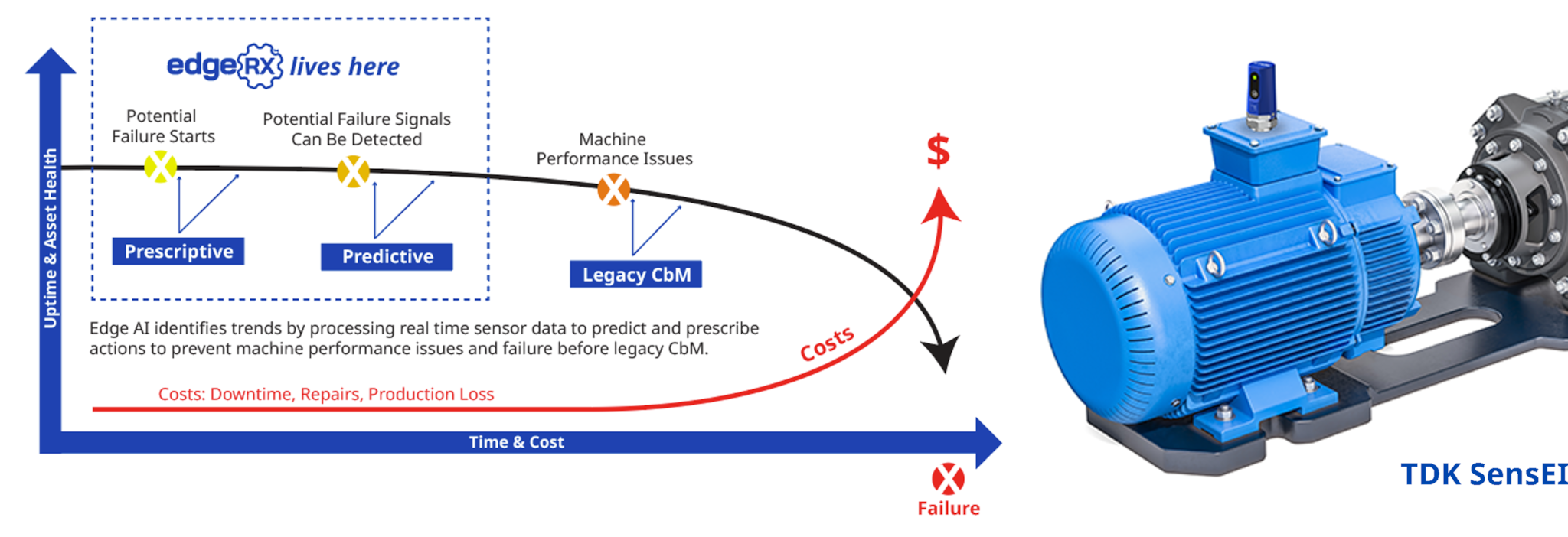

Industrial machine health monitoring is entering a new era with the integration of AI and edge computing. Instead of relying solely on periodic manual inspections or basic condition-based maintenance, today’s solutions use advanced AI algorithms running directly on edge devices to continuously monitor equipment health in real time. By processing sensor data—such as vibration, temperature, and acoustic signals—at the source, organizations gain instant, actionable insights without the delays or bandwidth constraints of cloud-only systems.

Predictive maintenance, powered by these technologies, enables engineers and maintenance teams to forecast equipment failures before they happen. This proactive approach allows for scheduled interventions, minimizing unexpected downtime and extending the lifespan of critical machinery. Going a step further, prescriptive maintenance leverages machine learning to recommend specific actions that optimize performance and prevent issues, turning raw data into strategic guidance. For 30–40s engineers and designers, these capabilities mean less firefighting, more efficient resource allocation, and a shift from reactive to truly strategic maintenance planning.

edgeRX Platform Overview

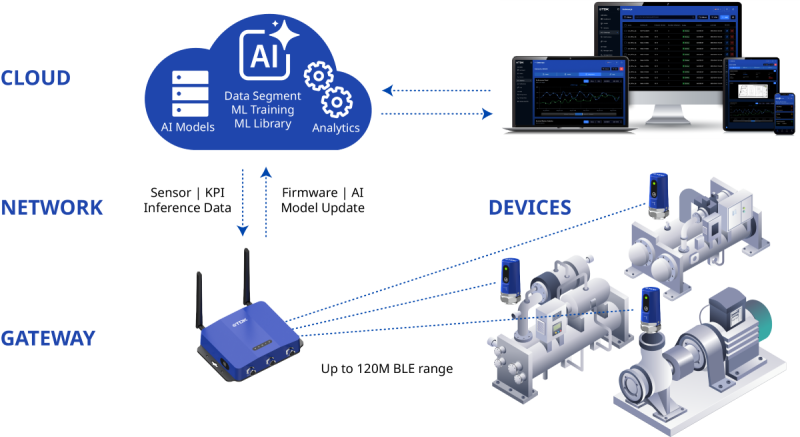

edgeRX is an industrial machine health monitoring platform offering a complete solution for optimal equipment performance. Utilizing advanced AI and edge computing, it delivers real-time monitoring, predictive maintenance insights, and actionable alerts directly on machines. The platform is purpose-built to support continuous condition monitoring, rapid anomaly detection, and the scheduling of targeted maintenance interventions.

edgeRX Equipment

edgeRX Sensor

The edgeRX Sensor continuously collects and analyzes critical data like vibration, temperature, and other performance metrics, providing real-time insights into machine health. Utilizing advanced edge computing, it processes data locally to reduce latency and quickly detect anomalies or potential failures. Its compact and durable design allows integration into various industrial environments, offering organizations a scalable and efficient tool for Machine Health monitoring and predictive maintenance.

edgeRX AI

The AI and ML capabilities within edgeRX are at the core of the platform. Leveraging AI and ML algorithms, edgeRX analyzes vast amounts of sensor data in real time, identifying subtle patterns and trends that might indicate potential issues. These algorithms enable predictive maintenance by forecasting equipment failures before they occur, reducing unplanned downtime and enhancing operational efficiency. edgeRX’s ML models continuously learn and adapt to evolving machine behaviors, ensuring increasingly accurate diagnostics and insights over time—driving better maintenance decisions and cost savings.

edgeRX Cloud

The cloud component of edgeRX’s Machine Health monitoring system acts as the backbone for data aggregation, storage, and advanced analytics. After the edgeRX Gateway transmits sensor data, the cloud platform securely processes and stores this information, enabling organizations to access historical trends and comprehensive insights. Utilizing scalable cloud infrastructure, edgeRX provides high-powered computing resources for in-depth analysis, reporting, and long-term model training that improve predictive maintenance accuracy.

edgeRX Dashboard

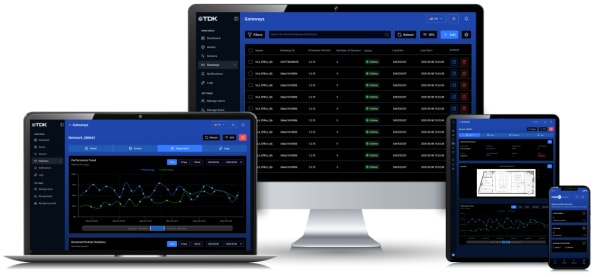

The edgeRX dashboard offers a user-friendly interface for monitoring machine health and performance. With real-time analytics and customizable visuals, users can quickly check key metrics like vibration and temperature. It combines data from edge devices and the cloud into clear formats like charts and alerts. The dashboard also supports trend analysis, threshold management, and maintenance scheduling—helping organizations operationalize predictive maintenance strategies.

edgeRX Target Industries & Equipment

| Smart Manufacturing (Primary) |

| Smart Energy |

| Smart Buildings |

| Other w/ Motors/ Pumps |

|

|

Generators |

|

Compressors |

|

Pumps |

|

Motors |

|

Complex Machines |

edgeRX Key Industries

* Smart Manufacturing

In manufacturing, precision and efficiency are vital. TDK SensEI’s AI solutions empower manufacturers by optimizing production processes, enhancing Machine Health monitoring, and significantly reducing downtime through advanced predictive maintenance. By harnessing Edge AI, our solutions provide real-time insights into equipment performance and product quality, enabling swift and accurate decision-making that supports Industry 4.0 objectives.

* Smart Energy

In the energy sector, achieving high efficiency and reliability is essential. TDK SensEI’s AI solutions support energy providers across wind, solar, hydro, and oil & gas by optimizing generation processes, enhancing equipment health monitoring, and reducing downtime through predictive maintenance. Leveraging Edge AI, our solutions deliver real-time visibility into asset condition, improving reliability and asset life-cycle management.

* Smart Building

In smart buildings, efficiency and sustainability are key. TDK SensEI’s AI solutions help building managers optimize energy usage, enhance Machine Health monitoring for critical equipment (HVAC, pumps, elevators), and reduce maintenance costs through predictive maintenance. Real-time insights enable timely interventions that keep systems running efficiently and occupants comfortable.

TDK SensEI demonstrates the transformative power of AI solutions across various industries, driving innovation and operational excellence through actionable Machine Health monitoring and predictive maintenance.

Case Study for edgeRX

Monitoring Bearing Conditions at TDK Mikumagawa Factory

Problem: Mikumagawa factory faced a significant issue with several guide rollers whose bearing conditions were unknown. In the roll-to-roll process, numerous guide rollers are installed, which increases the inspection workload. Maintenance was only performed when signs of defects were detected, posing a substantial risk, as bearing failures could lead to the entire factory's operations being brought to a halt, resulting in significant financial losses. The inability to predict and prevent bearing failures threatened the factory’s productivity and overall efficiency.

Solution: To address this challenge, the factory installed the edgeRX predictive maintenance platform, designed to monitor the bearing condition on all the guide rollers throughout the facility. edgeRX utilized advanced sensors and AI algorithms to continuously analyze bearing performance and detect early signs of potential faults. This real-time Machine Health monitoring system enabled the early identification of issues, allowing timely interventions to prevent bearing failures.

Result: The implementation of edgeRX significantly improved the factory's operational efficiency by providing the ability to monitor bearings on guide rollers across the entire facility. The system’s real-time analysis and predictive capabilities allowed for the quick identification of bearings that exhibited signs of potential failure. This proactive approach to maintenance not only minimized unexpected downtime but also reduced maintenance costs and ensured the continuous operation of the factory, ultimately enhancing productivity and financial savings.

Motor Health Monitoring at TDK SAE Factory

Problem: A large SAE factory faced a critical issue with several motors whose condition was unknown. The uncertainty surrounding the health of these motors posed a significant risk, as motor failures could bring down the entire factory operation, leading to substantial financial losses. The inability to predict and prevent motor failures threatened the factory’s productivity and overall efficiency.

Solution: To address this challenge, the factory installed the edgeRX predictive maintenance platform, which was designed to monitor anomalies in all the motors throughout the facility. edgeRX utilized advanced sensors and AI algorithms to continuously analyze motor performance and detect early signs of potential faults. This real-time Machine Health monitoring system allowed for the early identification of issues, enabling timely interventions to prevent motor failures.

Result: The implementation of edgeRX significantly improved the factory's operational efficiency by providing the ability to monitor machine health across the entire facility. The system’s real-time analysis and predictive capabilities allowed for the quick identification of motors that exhibited signs of potential failure. Notably, edgeRX detected an imbalance in a motor due to compressed mountings, enabling technicians to address the issue before it led to a complete motor failure. This proactive, predictive maintenance approach minimized unexpected downtime, reduced maintenance costs, and ensured continuous operation—resulting in higher productivity and cost savings.

AOI Overview

Automated Optical Inspection (AOI) is a key technology in manufacturing that uses high-resolution imaging and computer vision to automatically detect defects on products such as soldering errors, missing components, and surface anomalies. Its importance lies in its ability to ensure product quality, reduce manual inspection time, and prevent costly downstream failures. AOI complements Machine Health monitoring and predictive maintenance by focusing on external and process-quality defects that sensor-based monitoring may not detect.

edgeRX Vision Overview

edgeRX Vision is an advanced defect detection platform designed for high-throughput manufacturing. Using AI and computer vision, it identifies micro-defects as small as 1 mm x 0.5 mm with exceptional accuracy and speed—up to 2,000 parts per minute. Designed to enhance existing AOI capability with AI, edgeRX Vision reduces false positives and unnecessary machine stoppages, enabling smoother operations, higher yield, and significant revenue gains through increased throughput and quality control. When combined with edgeRX sensor-based Machine Health monitoring, edgeRX Vision helps deliver a holistic factory health solution that supports both product quality assurance and predictive maintenance workflows.

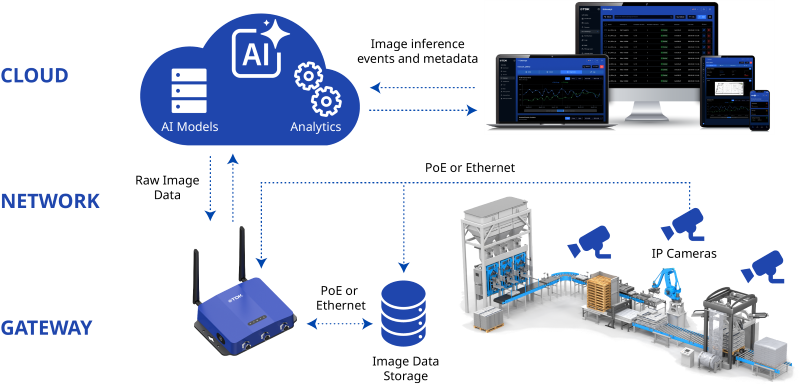

edgeRX Vision Architecture Overview

Benefits of edgeRX Vision

edgeRX Vision is designed to be a complement to the edgeRX sensor suite and solutions. Condition-based monitoring (CbM) sensors and computer vision are best used together: sensors excel in internal health monitoring (e.g., bearing wear), while vision systems excel in external/process monitoring such as product quality. This integrated approach enhances both Machine Health monitoring and predictive maintenance, enabling a more holistic, data-driven view of factory health that reduces false positives, prevents unplanned stops, and improves overall yield.

|

|

|

|

|

|

|

|

|

|

|

|

Case Study for edgeRX Vision

|

Problem: |

Solution: |

Result: |

・ Inaccurate Damage Detection ・ High Rate of False Positives ・Efficiency and Quality Concerns | ・ AI Vision Integration ・False Positive Reduction ・Seamless Transition | ・Improved Detection Accuracy ・Reduction in False Positives ・Increase in Production Output |

FAQ

For FAQs, please visit FAQs – SensEI by TDK.

Download the edgeRX Product Catalog (PDF)

[FILE NAME]edgeRX_product_overview_250728_en.pdf

[CAMPAIGN NAME]edgeRX_product_overview_250728_en