Solution Guides

Solder Crack Countermeasures in MLCCs Outline

Fig. 1: Appearance of a solder crack

(cross-section)

Major causes of solder cracks

Fig. 2: Major causes of solder cracks and their impact

Solder cracks on MLCCs developed from severe usage conditions after going on the market and during manufacturing processes such as soldering. The following causes can be listed as the major cause of solder cracks.

(1) Thermal shock (heat shock), heat fatigue caused by temperature cycle

Solder cracks occur when heat stress is applied to a solder joint due to the difference in the thermal coefficients of the MLCC and PCB, in an environment in which changes between high temperatures and low temperatures are repeated. In addition, it can also occur when temperature control is insufficient during the process of soldering.

(2) Lead-free solder

Lead-free solder, which started to be used due to environmental considerations, has properties of being rigid and fragile, and has a higher risk of solder cracks compared to conventional eutectic solder; therefore, caution is required when using it.

Applications and boards that specially require solder crack countermeasures

Fig. 3: Applications that require solder crack countermeasures

Automobiles, vehicles (engine room)

Infrastructures placed outdoor and required to be maintenance-free for an extended period of time

Solder cracks occur mainly because of thermal fatigue due to thermal shock or temperature cycles or the use of lead-free solder, which is hard and fragile.

Therefore, special caution is required when mounting MLCCs to areas near high-temperature heat generation parts where sudden temperature changes (thermal shock) such as rapid heating or rapid cooling occur, including the engine rooms of a cars.

In addition, among products that experience repeated temperature changes such as outdoor equipment, infrastructure including solar or wind power generation facilities or base stations realize the requirement of being maintenance-free for an extended period of time; therefore, it is necessary to pay attention to solder crack countermeasures.

1 Metal terminals "disperse" thermal shock

MEGACAP

Fig. 4: MEGACAP structure

MEGACAP is a type of MLCC in which metal caps are attached to the terminal electrodes, and is available in single and double stacked configuration (Fig. 4).

Joint strength against thermal shock

TDK’s MEGACAP is highly effective in preventing solder cracks. Fig. 5 shows a comparison of cross-sections before and after a thermal shock test with 3000 cycles. It is clear that the solder of the regular terminal product has deteriorated more than that of MEGACAP.

Fig. 5: Thermal shock test result (comparison between a regular terminal product and MEGACAP)

[Test condition] Solder: Lead Free, Sn/3.0Ag/0.5Cu Thermal shock: -55 to +125℃ /30 minutes each

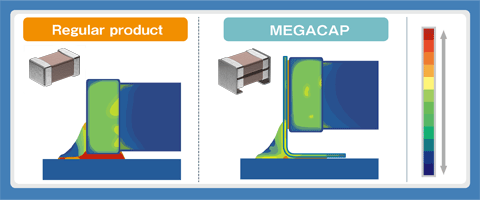

Comparison of board flexure simulation results

Fig. 6: Board flexure simulation

(comparison between a regular product and MEGACAP)

[Condition] Board flexure (2mm), 3225 size

Fig. 6 shows the results of a board flexure simulation for a regular product and MEGACAP bonded to boards. Stress caused by thermal shock or board flexure concentrates on solder joints; therefore, solder cracks easily occur on the regular product, while the metal terminals absorbs stress and reduces occurrences of solder cracks in MEGACAP.

[ MEGACAP features ]

- Provided with metal caps over the external electrodes that absorb stress caused by mechanical shocks. Also features improved vibration resistance.

- The stacked type can reduce mounting areas in circuits in which two capacitors with an equal capacitance are used in parallel.

- Features lower ESR and ESL compared to those of aluminum electrolytic capacitors.

[Major applications]

- Automotive applications (EPS, ABS, EV, HEV, LED lamps, etc.)

- Smoothing circuits, DC-DC converters, LEDs, HIDs

- Application in environments with severe temperature changes, piezoelectric effect countermeasures

[ MEGACAP ] Product information and sample purchase

Commercial grade

Automotive grade

2 Equipped with resin layers that absorb stress applied to solder joints and resistant to dropping

Soft termination

Fig. 7: Difference between a regular terminal product and Soft termination

In the terminal electrode of a regular MLCC, the Cu underlayer is plated with Ni and Sn. Soft termination is a type of MLCC in which a conductive resin layer is provided between the Cu and Ni plating layer (Fig. 7).

The resin layer absorbs stress accompanying expansion or shrinkage of the solder joints due to thermal shock or flex stress on the board and prevents occurrences of solder cracks.

Approximately ½ bond strength decrease rate compared to conventional products

TDK’s MLCCs with resin electrodes feature outstanding thermal shock resistance. Fig.8 is a graph comparing the bond strength obtained in a bond strength test after experiencing thermal shock between a regular terminal product and a resin electrode product. Data of 3,000 cycles of thermal shock (-55 to +125℃/3000 cyc.) is shown. The bonding strength of the regular product decreases approximately 90%. On the contrary, it decreases only about 50% in the conductive resin terminal product.

Fig. 8: Bond strength decrease rate (comparison between a normal terminal product and Soft termination)

[ Features of Soft termination ]

- Improves resistance to bending, drop impacts, and thermal shock (heat cycle) of the board.

- Conductive resin absorbs external stress and protects solder joints and components.

[ Major applications ]

- Countermeasure against or prevention of "flex cracks" of units that require handling of boards to which multilayer ceramic chip capacitors have been soldered

- Electric circuits mounted to aluminum circuit boards, SMT applications requiring strong resistance to bending, in which reliability of solder joints can become an issue

- PCs, smart keys, car multimedia, switching power supplies, base stations, automotive applications (ECU, ABS, xEV, etc.)

[ Soft termination ] Product information and sample purchase

Commercial grade

Automotive grade

Summary of "Solder Crack Countermeasures in MLCCs"

- "Solder cracks" occur when stress is applied to joints of a capacitor and a board, which may cause dropout of components or open circuit failures.

- Special caution is required when applying capacitors in equipment exposed to thermal shock or temperature cycle including automobile engine rooms or other equipment with heat sources, infrastructure that does not require maintenance for an extended period of time, or solder joints using hard and fragile lead-free solder.

The features of each product are summarized in Table 9.

Please select products that suit your purposes and use them to improve the reliability of your products.

Table 9: Comparison of solder crack countermeasures for MLCCs

![Fig. 3: Applications that require solder crack countermeasures [Automobiles, vehicles (engine room)]](/system/files/sog_mlcc_solder-crack_mlcc01-005_de.png)

![Fig. 3: Applications that require solder crack countermeasures [Infrastructures placed outdoor and required to be maintenance-free for an extended period of time]](/system/files/sog_mlcc_solder-crack_mlcc01-006_de.png)

![[ Features of Soft termination ]](/system/files/sog_mlcc_solder-crack_mlcc01-018_de.png)