- Kondensatoren >

- Keramik-Vielschichtkondensatoren (MLCC)

A.

No. The termination used for epoxy mounting serves several purposes.

The addition of copper reduces the silver migration rate of the termination, which increases the amount of time it takes for a short to develop across the capacitor.

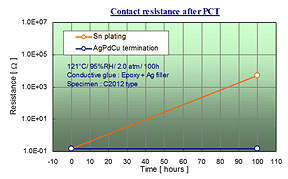

The conductive glue can absorb water, which would cause the Sn plating on a standard termination to oxidize. This increases the contact resistance between the MLCC and the conductive epoxy significantly (approximately 100 times greater after 100 hours), which leads to energy losses and heat generation. The AgPdCu alloy does not have the same oxidation issues as Cu/Ni/Sn and maintains a stable contact resistance.

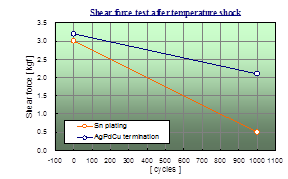

Finally, during operation, temperature cycling can result in micro-cracks developing between the standard Cu/Ni/Sn termination and the epoxy, resulting in drastic reduction in shear force required to remove the chip from the board. The AgPdCu termination reduces the rate at which these micro-cracks develop because the silver contained in the termination and the conductive adhesive have a strong affinity for each other.

Figure 1: Contact resistance over time.

Figure 2: Shear force after temperature cycles.

>>Multilayer Ceramic Chip Capacitors Product site

For any other product-related questions or inquiries, please contact us throughone of our sales representatives or this website.