Q.

What are the factors that cause chip standing (Tombstone phenomenon, Manhattan phenomenon) during reflow?

- Kondensatoren >

- Keramik-Vielschichtkondensatoren (MLCC)

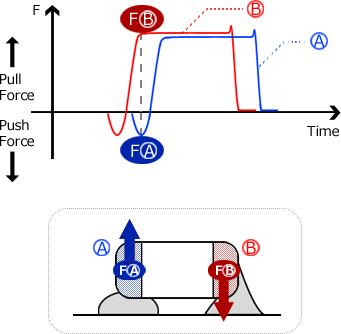

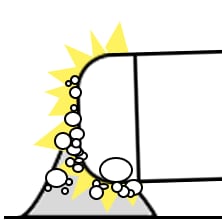

A. There are two main factors. The first is when there is an imbalance between the forces FA and FB applied to both terminal electrodes. The second is when the air trapped in the solder paste becomes bubbles when heated, pushing up the terminal electrodes from below.

Factor 1

Factor 2

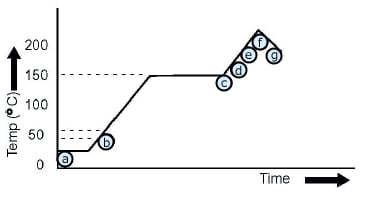

| Profile Region | Soldering Effect on Component | ||

|---|---|---|---|

| a | |||

| b |

Flux separates from paste and begins to wick up the component. |

||

| c |

Some flux evaporates; the solder paste looses viscosity and runs together between PCB pads |

||

| Good | Factor 1 | Factor 2 | |

| d 175~185°C |

Chip is pushed up |

Unequal solder melting |

|

| e 185~195°C |

Chip is pulled down |

Unequal solder wetting |

Flux |

| f 220~230°C |

Foam generates and one end of the chip is lifted up |

||

| g |

No Tombstoning |

Tombstoning |

Tombstoning |

>>Multilayer Ceramic Chip Capacitors Product site

For any other product-related questions or inquiries, please contact us throughone of our sales representatives or this website.