C43 / C44 series - Pressure sensor DIEs for high burst pressure requirements in the automotive and industrial segment

Contents

- General information piezo-resistive technology

- Description of C43 / C44 product family

- Highlight features of C43 / C44 DIEs

- 1. Increased burst pressure

- 2. Long term stability

- 3. Further opportunities for existing sensor packages - Optional special features for MEMS DIEs C44

- Product overview

- Application examples

- 1. Automotive applications

- 2. Industrial applications - Related Links

General information piezo-resistive technology

TDK provides a wide range of highly accurate, piezoresistive pressure sensing MEMS DIEs at different pressure ranges and footprints. TDK DIEs offer high sensitivity and versatile design features for enhanced media resistance, ease of processing, and the ability to provide a reliable and stable signal over lifetime.

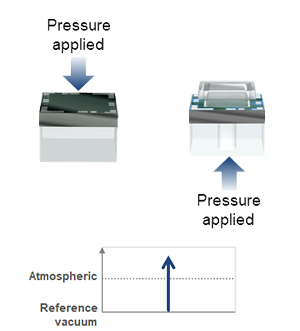

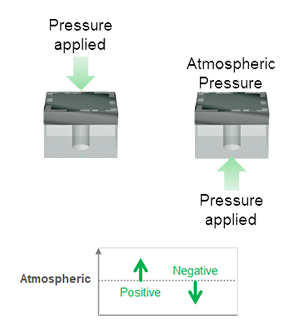

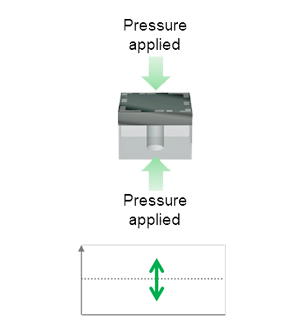

| Absolute | |

|---|---|

|

| Gauge | Differential | |||

|---|---|---|---|---|

|

|

|||

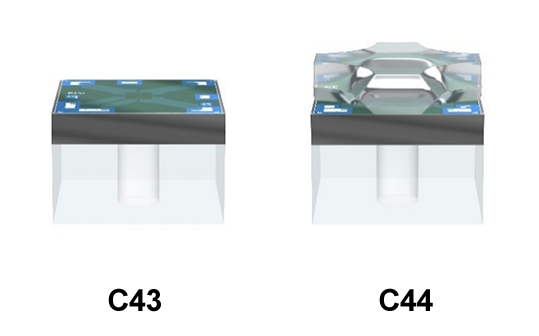

Description of C43 / C44 product family

The C43 and C44 DIEs provide gauge, front and backside absolute pressure measurements options and are available with an operating pressure range from 0 … 10 bar up to 0 … 40 bar at a temperature range of -40 °C to +150 °C.

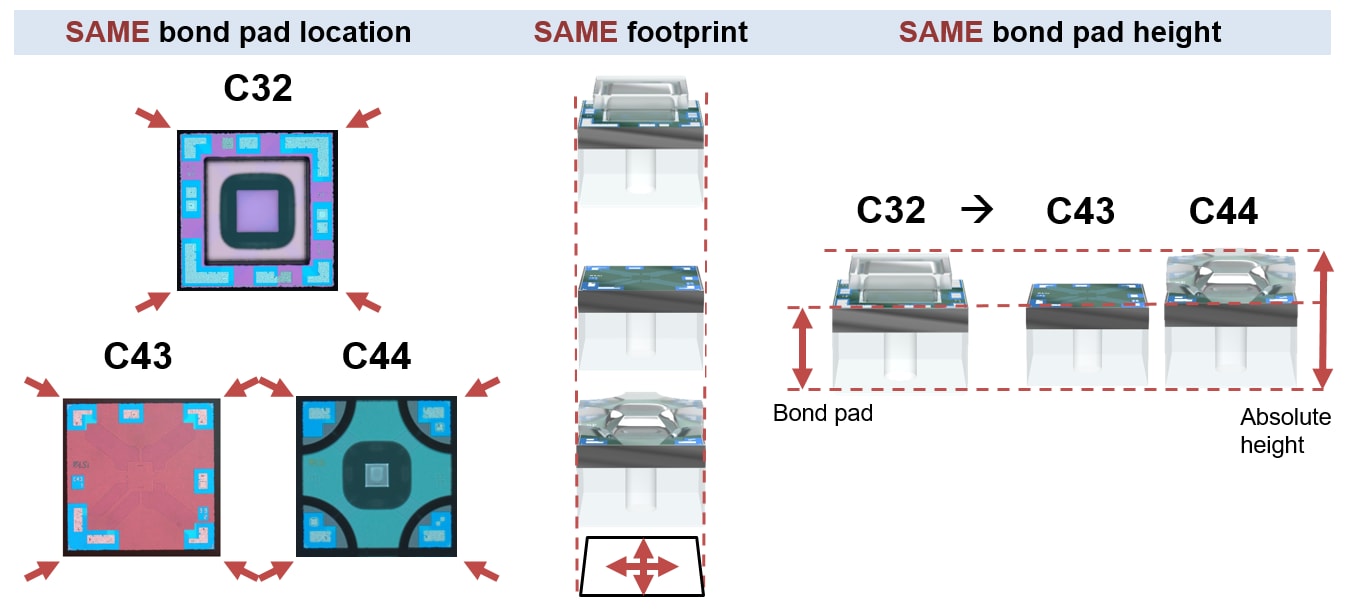

The C43 / C44 product family is an extension of the successful C32 DIE series.

Especially for the C44 backside absolute, the media pressure is applied from the backside of the DIE, thus it allows a clear separation between electronics on the topside and application fluids or gasses within the application.

Highlight features of C43 / C44 DIEs

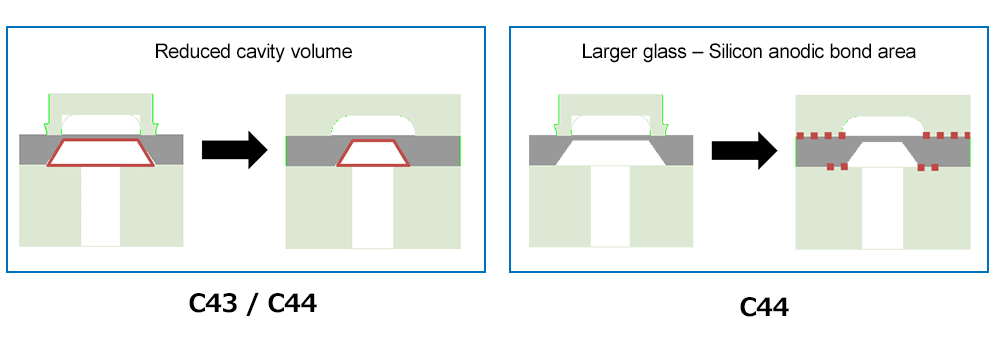

1. Increased burst pressure

The C43 / C44 series complement the TDK pressure sensor DIE portfolio for high-pressure applications with a significantly increased burst pressure of up to 150bar.

This serious burst pressure increase is made possible due to larger anodic glass bond area and reduced cavity volume.

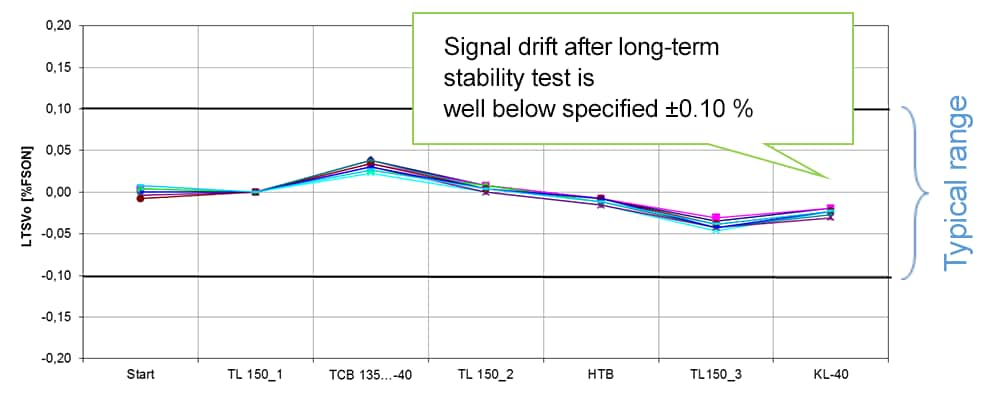

2. Long term stability

High long-term stability of output signal over lifetime, which is typically within ±0.10 % of the output signal at full scale. Furthermore, an electric shielding is implemented direct into the MEMS layer systems to reduce electromagnetic and electrochemical impacts on the DIE’s performance.

Test flow:

| Test | Meaning of the tests |

|---|---|

| Start | Measure of offset voltage after mounting |

| TL150 – 1 | Temperature load without bias at 150 °C for 15 h to post cure the samples |

| MR – 1 | initial MR in the temperature range -40°C to 135°C (measurement of output characteristic) |

| TCB | Temperature cycle bias test with 10 temperature cycles at -40 °C < T < 135 °C, dT/dt = 1 K/min, VDD = 5V (see measurement report TCB) |

| TL150 – 2 | Temperature load without bias at 150 °C for 15 h |

| HTB | Temperature load at 150 °C for 168 h with a bias of 10 V (see measurement report HTB) |

| TL150 – 3 | Temperature load without bias at 150 °C for 15h |

| KL – 40 | Temperature load at -40 °C without bias for 15h |

| MR – 2 | MR in the temperature range -40°C to 135°C (measurement of output characteristic) |

For further explanation for the mentioned tests and definition of long-term stability refer to TDK standard AS100001 in chapter “Reliability data” on the internet.

3. Further opportunities for existing sensor packages

Existing customers with higher burst pressure requirements can use the C43 and C44 in the same sensor package as for the current C32.

The C43 / C44 series is an extension of the successful C32 DIE family.

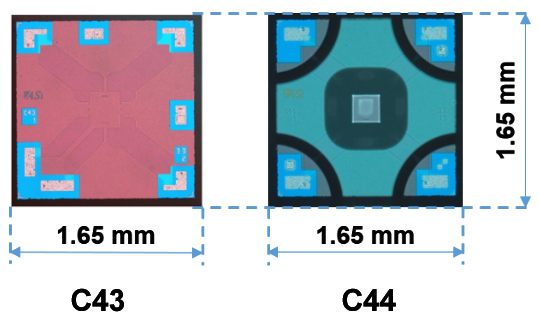

It has the same bond pad layout, footprint and bond pad height as the existing C32 DIE, but with higher burst pressures.

Optional special features for MEMS DIEs C44

| 1 | Absolute pressure sensing element with solderable back side metallization ・For a robust solder joint between pressure sensing element and sensor package, the C44 is available with a solderable metallization on the DIE backside. ・This enables a significant media resistance combined with high mechanical robustness |

|

| 2 | Gauge pressure measurement ・Designed for gauge pressure measurement, the C44 is bulit up without glass and optimised as a most cost sensitive option. ・Robust design due to 525µm thick silicon ・Miniturized package: 1.65 × 1.65 × 0.525 mm3 |

Product overview

| Series | Pressure measurement | Die size (mm3) | Media | Products |

|---|---|---|---|---|

| C43 | Absolute, front side (open bridge) |

1.65 × 1.65 × 1.1 | Dry non-aggressive gases | Link |

| Gauge (open bridge) |

1.65 × 1.65 × 1.1 | Non-aggressive gases and fluids Measured media (back side) | Link | |

| C44 | Absolute, back side | 1.65 × 1.65 × 1.5 | Non-aggressive gases and fluids | Link |

| Gauge (without glass) | 1.65 × 1.65 × 0.525 | Non-aggressive gases and fluids Measured media (back side) | Link |

Application examples

1. Automotive applications

In the automotive industry, sensors measure the pressure of various media to support powertrain management and safety systems. For combustion engines, the sensors support a precise engine control for low fuel consumption and is required to enable exhaust gas treatment for a reduction of harmful emissions. The sensors need to support electrified drives for battery management or hydrogen fuel cell applications. Further automotive components like braking, transmission, air-suspension or Heating, ventilation and air conditioning (HVAC) request accurate pressure monitoring for effective functioning.

Systems containing fluids such as hydraulic oil may create pressure spikes, which can potentially damage the sensor DIEs. The C43 / C44 DIEs with specified high burst pressures have a higher capability for operating under such peak pressures, which reduce the risk of DIE failure.

Long-term stability and high accuracy is mandatory to meet the latest system requirements.

2. Industrial applications

Pressure sensors supply data for industrial equipment and systems in order to control and diagnose, for instance hydraulically and pneumatically operated machines or Heating, ventilation and air conditioning systems (HVAC) in buildings or energy and water management. This makes them key components in measurement and control technology.

Applications using fluids require higher burst pressures than systems filled with gases. There are high-pressure peaks during the initial operation of pumps, valves or actuators. The C43 / C44 series offer high value for such applications requiring high burst pressures.

Contact Information

Related Links

Product Portal

- Sensor Solution Provider

- Wide variety of sensors and sensor systems portfolio as Sensor Solution Provider

- Sensors and Sensor Systems Product Information

- A comprehensive guide to information on Sensors and Sensor Systems from the TDK Group.

- Pressure Sensors Product Information

- A comprehensive guide to information on Pressure Sensors from the TDK Group.

- Pressure Sensor Transmitters Product Information

- A comprehensive guide to informationon Pressure Sensor Transmitters from the TDK Group.

- Barometric Pressure Sensors Product Information

- A comprehensive guide to information on Barometric Pressure Sensors from the TDK Group.