- Kondensatoren >

- Keramik-Vielschichtkondensatoren (MLCC)

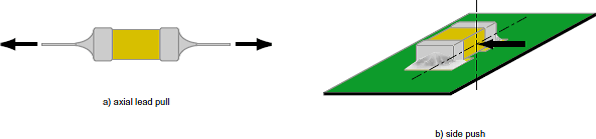

A. Terminal adhesion is the amount of force required to remove a component's termination from its body. It is most often evaluated by an axial lead pull or side push test. It is typically expressed in kilograms and is dependent upon component case size.

Figure 1: Traditional terminal adhesion tests

The axial lead pull is the best measure of a component’s true terminal strength, but the side push method takes into consideration the SMT process as a whole.

Note: The side push method is heavily dependent upon solder amount and the push point on the component.

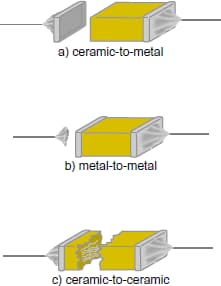

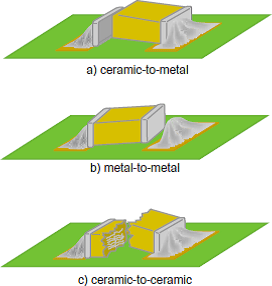

The magnitude of terminal adhesion should always be discussed together with the failure mode. The three basic modes of failure are illustrated below.

Figure 2: Failure modes, lead pull

Figure 3: Failure modes, side push

The failure mode can change with varied solder fillet heights. A ceramic-to-ceramic or metal-to-metal failure mode typically yields the highest strengths and is therefore generally preferred.

>>Multilayer Ceramic Chip Capacitors Product site

For any other product-related questions or inquiries, please contact us throughone of our sales representatives or this website.