Solution Guides

Summary of Flex Crack Countermeasures Using High-reliability MLCCs

4 Metal frame relieves flexure stress and reduces load applied to ceramic element

MEGACAP (with metal frame)

MEGACAP is a product of MLCC with metal frame attached to the terminal electrodes. MEGACAP has excellent resistance to mechanical stress because the flexible metal frame relieves stress by thermal shock and board bending. In addition, the stacked type is effective in mounting area reduction because twice capacitance functions by the stacked structure.

Fig. 19 Structure comparison

No element cracks were observed even after board was flexed up to 10mm

The effect can be confirmed by board flexure test. Whereas element cracks were observed after the board flexure 10mm in case of standard type, with the MEGACAP, no cracks were found.

Fig. 20 Results of board flexure test

【Advantages of MEGACAP】

- Excellent resistance to mechanical stress and thermal shock by metal frame

- Twice capacitance functions by stacked structure

- C0G type having excellent stable temperature and DC-bias characteristics is also available

- Mounting on aluminum board is applicable

【Major applications】

- Smoothing and decoupling applications requiring high capacitance

- Resonant circuit of wireless power transfer, etc.: C0G type

【MEGACAP】 Product information and sample purchase

Commercial grade

Automotive grade

5 Integration of high capacitance, high reliability and low resistance by original structure

MEGACAP (low resistance, inline type)

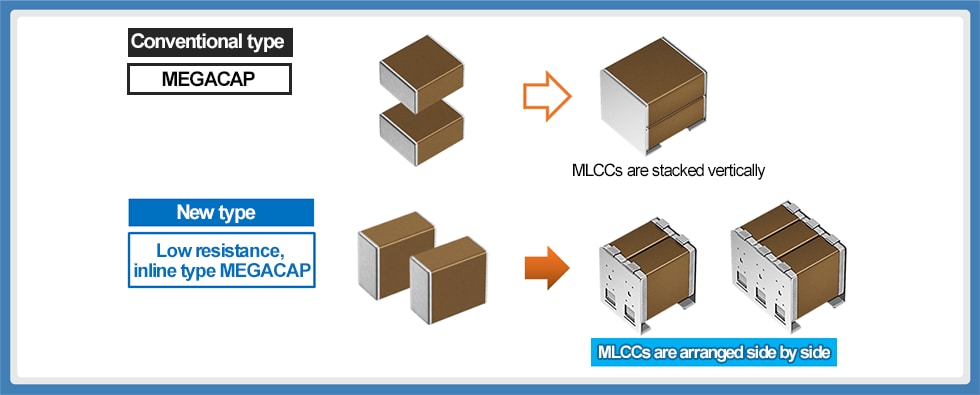

MEGACAP has metal frame to provide mechanical stress relief, however, the frame has additional resistance including the ESR characteristic. With the aim of suppressing this disadvantage, new type of MEGACAP with original structure has been developed. The feature of the structure is that MLCCs are arranged side by side.

Fig. 21 Low resistance, inline type with original structure

Inline structure keeps product height and impedance/ESR from increasing

In case of increasing the number of MLCCs of conventional type, product height and center of gravity go up because MLCCs are stacked vertically. Furthermore, ESR/ESL increase as the distance between upper MLCC and PCB becomes longer. Because of these disadvantages, increasing the number of MLCCs with conventional type becomes difficult. In contrast, new MEGACAP does not have these disadvantages since MLCCs are arranged side by side. As a result, whereas usable MLCCs of conventional type is up to two, new type has mass-produced double-type and triple-type.

Fig. 22 Advantages of new MEGACAP

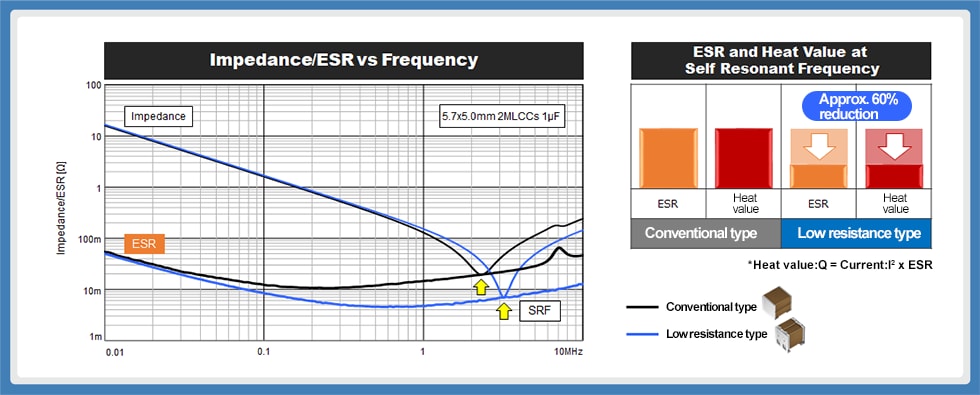

Reduction in Impedance/ESR

The effect is shown in the impedance/ESR frequency characteristics. The resistance value of the new type (blue) is lower than conventional type(black). At the self resonant frequency (SRF), the ESR of new type is approximately 60% lower than the conventional type, and a similar reduction in heat generation can be expected (heat value is proportional to ESR).

Fig. 23 Impedance / ESR frequency characteristics, ESR / heat value at self resonant frequency

【Advantages of low resistance, inline type MEGACAP】

- Integration of high capacitance, high reliability and low resistance by original structure due to inline structure which MLCCs are arranged side by side and optimization of metal frame composition

- Excellent resistance to mechanical stress and thermal shock by metal frame

【Major applications】

- Smoothing and decoupling applications requiring high capacitance

- Resonant circuit of wireless power transfer, etc.: C0G type

【MEGACAP (low resistance, inline type)】 Product information and sample purchase

Commercial grade

Summary of Flex Crack Countermeasures Using High-reliability MLCCs

- A risk of short mode failure increases when a crack occurs in a ceramic element and moisture penetrates into the crack as well.

- Special caution is required especially in case of the following applications.

- Equipment which is constantly exposed to vibrations and/or shocks

- Equipment which is exposed to frequent shock by dropping

- Handling which excessive board flexure stress is applied to substrate during manufacturing

- TDK offers five series of high-reliability MLCC products which are designed to reduce the risk of flexure stress related to short circuit. Please select suitable products from these series and use them to improve the reliability of your equipment.

Fig. 24 Advantages of high-reliability MLCCs