The New Reference LAN Pulse Transformer

The New Reference LAN Pulse Transformer

In recent years, LAN connectors have become standard equipment not only on computers and other IT products but also in digital TV sets as well as many other types of audiovisual appliances and consumer products. Pulse transformers are key components used in such LAN interfaces. The transformers must convey pulse signals at high speed and at the same time provide other functionality such as insulation between the input and output. TDK has applied its extensive technological know-how gained in developing SMD (surface mount device) type common mode filters to create a new kind of SMD pulse transformer manufactured using an automated coil winding technique. Conventional devices with hand-laid windings suffer from various problems such as uneven characteristics due to manufacturing tolerances. By contrast, the new pulse transformers from TDK offer excellent uniformity and provide comparable performance as existing products at a much smaller footprint. The ALT series is bound to become a new reference in this field.

Ethernet Became Dominant LAN Format Along With Progress of Computers

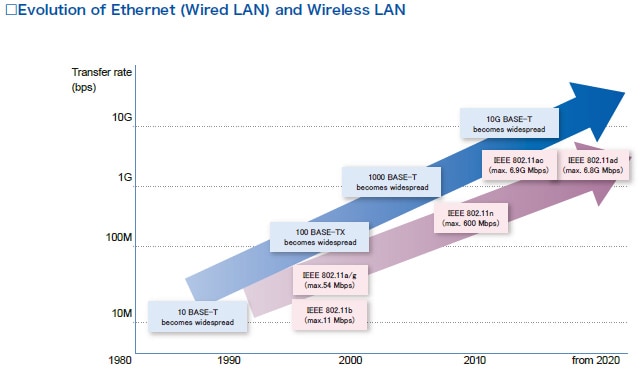

The Ethernet standard, which is now is the dominant worldwide format for LAN (local area networks), was developed in the early 1980s in the U.S. It was originally designed to link workstations in research facilities, businesses, and similar professional environments. But along with the evolution of the personal computer, LAN became a widely adopted solution for connecting multiple PCs, and the LAN market grew by leaps and bounds. A linkup of separate LANs over a greater distance is called a WAN (wide area network), while a connection between multiple computers and audiovisual devices in a home is called a home network or home LAN. Unlike wireless LANs, an Ethernet LAN requires a cable connection, but this enables very reliable data transmission at much higher speeds.

There are various Ethernet formats which differ in aspects such as the type of cable connection and the transfer speed. These are defined by the respective standards and indicated by terms such as 100BASE-T or 1000BASE-T. The former is rated for a transfer speed (throughput rate) of 100 Mbps, while the latter achieves speeds as high as 1000 Mbps (1 gigabit per second). The "T" indicates that the format uses twisted pair cable.

Pulse Transformer: Key Component of a LAN Interface

Electronic devices equipped with a LAN connector have an integrated LAN adapter that allows the device to be linked to a network simply by plugging in the cable. Before LAN adapters became standard on the motherboards of PCs, they usually were available in the form of plug-in cards designed to be inserted into a slot of the computer. One of the reasons why adapters now are integrated in computers is the spread of broadband Internet connections.

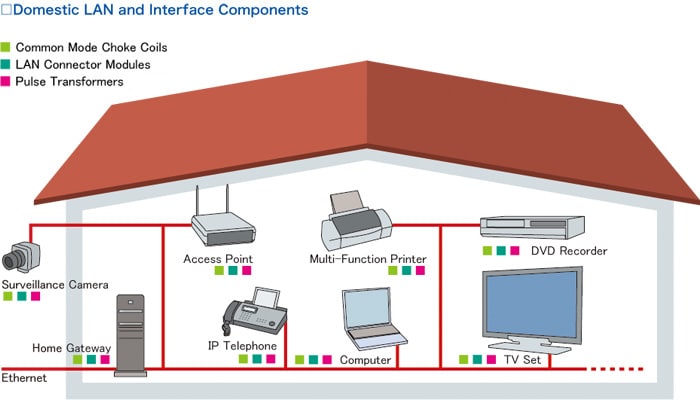

A LAN connector, also called a LAN port, looks somewhat similar to a modular phone jack, with slightly bigger dimensions. This is called an RJ45 connector. Internally, the RJ45 connector signals are routed via common mode choke coils (filters) to the pulse transformer and then to the transceiver IC. A LAN connector module integrates the RJ45 connector, common mode choke coils, and pulse transformer into a single compact unit.

The pulse transformer is a special kind of transformer designed to transmit pulse waveform signals. Unlike a power transformer, its purpose is not to transmit power; therefore, it can be made considerably more compact, allowing it to fit into the connector module.

Conventional Method: Manual Winding on Toroidal Core

A pulse transformer employs a simple construction built around a toroidal (ring-shaped) core on which the primary and secondary coils are wound. However, although the operation principle and construction are simple, pulse transformers are actually quite difficult electronic components to build well. Aspects such as design, choice of core material, and winding method affect the outcome considerably, and uniform characteristics are not easy to achieve.

Compared to other transformers with cores that inherently have air gaps, a toroidal transformer has lower leakage flux and can therefore deliver better performance. Consequently, pulse transformers traditionally were designed as toroidal transformers, but due to their shape, the coils normally are hand-wound because automated winding is difficult to implement. This unavoidably results in tolerances between finished units and presents an obstacle to stable quality and mass production.

New Manufacturing Method Based on a Breakthrough Idea

Not only personal computers but also many other types of equipment these days such as digital TVs and audiovisual appliances routinely come with LAN connectors. Pulse transformers for LAN applications therefore have become a highly sought-after product. If the toroidal core shape is taken as a given, automated winding is not feasible and the needs of the market are difficult to meet.

The ALT series of SMD pulse transformers from TDK represents a radical departure. By thinking outside the box, our engineers have come up with a solution that enables a manufacturing process that uses automated winding.

The development team took a hint from SMD type common mode filters that are used extensively as noise suppressing components. A common mode filter is similar to a pulse transformer in that it employs two windings on a toroidal core. To enable mass production, TDK developed a pioneering approach that uses automated winding on a drum core and then joins it with a flat plate core. It turned out that a very similar core construction and automated winding method as for SMD type common mode filters can in fact be applied to pulse transformers. This led to the development of the new SMD type pulse transformers.

Winding Design Requires Advanced Technical Know-How

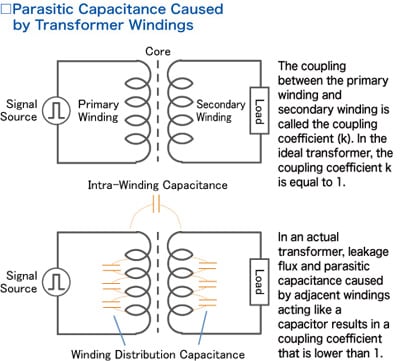

The strength of the coupling between the primary and secondary windings on a transformer is expressed as the coupling coefficient (k). In an ideal transformer, this would be 1, but in the real world, leakage flux and other factors result in a coefficient k that is smaller than 1.

A key aspect of transformer design therefore is the question of how to achieve a coefficient that approaches 1 as closely as possible. As described above, the air gap in a transformer core causes leakage flux leading to leakage inductance which degrades the performance of the transformer. By designing a new core shape that lends itself to automated winding, TDK was able to reduce the gap at the juncture between the drum core and plate core to less than half, resulting in a significant reduction of leakage flux.

The winding design also is important with respect to lowering the coupling coefficient. Transformer windings are subject to a phenomenon called parasitic capacitance that does not show up in circuit diagrams. Although windings are electrically isolated, the potential difference causes adjacent windings to act like the electrodes of a capacitor. This type of parasitic capacitance is called intra-winding capacitance. In addition, there is also another type of parasitic capacitance, namely the winding distribution capacitance between the primary and secondary winding. Reducing these types of parasitic capacitance involves a tradeoff, because this reduction results in increased leakage inductance. Achieving good winding design therefore requires advanced technical know-how that is not easy to come by.

Adopting Ferrite as the Ideal Core for a Pulse Transformer

Because pulse waveforms usually cover a very wide frequency range, the choice of core material is crucial to prevent excessive pulse waveform distortion that can degrade the signal.

For example, a pulse transformer for a 100BASE-T Ethernet connection is required to have an inductance value of at least 350 microhenry (µH) when a DC bias of 8 mA is applied. The outstanding DC superposition characteristics of ferrite therefore are highly desirable, since the magnetization curve remains linear also when a DC bias magnetic field is applied. (Waveform distortion increases towards the curved portion of the characteristics plot.) A ferrite material that offers both high magnetic permeability and high saturation flux density and that exhibits these characteristics over the entire temperature range existing in a normal LAN environment is required.

Making use of its extensive experience with ferrite technology, TDK developed a ferrite material optimized for pulse transformer applications. Both material composition and microstructure were carefully reconsidered to achieve this goal. In the ALT series, a new material that meets the technical requirements of next-generation high-speed LANs is used.

High Performance on a Par with Previous Products Achieved Through Automated Winding

The ALT series delivers the high reliability and performance required of a pulse transformer for LAN applications, and it does so in a compact SMD type package manufactured with automated winding, something that was considered very difficult to realize. As can be seen from the eye pattern shown at right, signal integrity is on the same level as with conventional products, although the SMD package is notably smaller.

The ALT series of pulse transformers not only utilizes automated winding for the coils, it also employs automated thermo compression bonding for the terminal electrodes and wires. With conventional products, manual wire processing and soldering are required. Automating these steps results in more uniform quality.

The manufacturing process for conventional products is semi-automated, with batch processing being employed for the stages from electrical testing to taping. By contrast, the manufacturing process for the ALT series is continuous and fully automated.

Smaller Footprint Results in Significant Space Saving

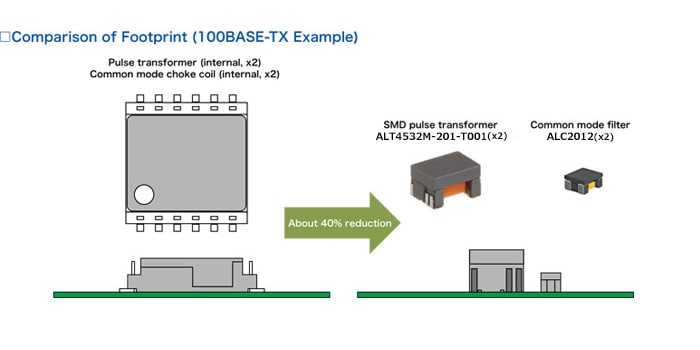

The pulse transformer is normally integrated in the LAN module along with the common mode choke coils and other parts. With conventional components, complex wiring as well as soldering tasks had to be performed manually when mounting the pulse transformer. The parts were then fixed with resin. Because the ALT series transformers are SMD components, they can be mounted along with other parts during the reflow stage, greatly simplifying the process and reducing the number of required work hours.

Another advantage is the more compact dimensions that contribute to space savings. When combined with noise removal according to the differential transfer method, the required footprint can be reduced by about 40 to 60% (using single-unit board mounting in combination with the ALC series common mode filters from TDK).

The ALT series like its predecessor products is designated by TDK as a fully lead-free "environment-conscious" product that completely eliminates lead and lead compounds and is compatible with lead-free soldering. The ALT series is also halogen-free and therefore suitable for companies that are engaged in efforts to completely eliminate halogen from their end products.

Towards Next-Generation High-Speed LAN Integrating Wired and Wireless Connections

Wireless LAN is becoming more widespread, but wired LAN still has a clear advantage in terms of high transfer rates, resistance to interference, and operation stability. Pulse transformers which are a key component for LAN applications will need to meet the performance requirements for next-generation Ethernet solutions.

Servers, routers, and similar equipment must support higher speeds and provide outstanding reliability, while compact dimensions and a low-profile form factor are design targets in notebook computers, digital TVs, hard disk recorders, game consoles, etc. In the factory automation sector, further performance improvements under a wide range of temperature conditions are called for.

Covering the entire spectrum from home use to industrial applications, the ALT series conforms to high performance specifications. As an industry first, these compact SMD type pulse transformers implement automated winding. The next-generation high-speed networks integrating wired and wireless connections will demand advanced component technology. Making full use of its extensive know-how in core technologies, namely materials technology, process technology, and evaluation & simulation technology, TDK is offering sophisticated LAN application products that meet these needs.

Major Features

- SMD type supporting automated winding, shape can be adapted to customer requirements

- Support for automated mounting, reflow soldering, and halogen-free applications

Major Applications

Consumer/industrial equipment with LAN interface such as digital home appliances, set-top boxes, PCs

Dimensional Drawing and Circuit Diagram

Major Specifications

| Part No. | ALT3232M-151-T001 | ALT4532M-171-T001 | ALT4532M-201-T001 |

|---|---|---|---|

| Inductance*1 | 150uH min. | 170uH min. | 200uH min. |

| Insertion Loss*2 | 2.5dB max. | 2.5dB max. | 1.5dB max. |

| Intra-Winding Capacitance | 25pF max. | 35pF max. | |

| Temperature Range for Use | -40 to 85°C | ||

| Form Factor | 3.2 x 3.2mm | 4.5 x 3.2mm | |

| Thickness | 2.9mm max. | 2.2mm max. | 2.9mm max. |

*1 DC Bias 8mA , 100kHz

*2 0.1 to 100MHz