Surface Potential Sensors EFS Series

Structure of Surface Potential Sensors

The probe part serving as the "eye" that senses the photosensitive drum surface potential consists of a chopper (tuning fork type oscillating plate) equipped with electric field line blocking shutters and a piezoelectric element for driving the shutters, a sensor electrode for detecting surface potential, and a preamplifier for impedance conversion (detection circuit) (Figure 1). This small piezoelectric actuator control mechanism that becomes the key component for sensing is contained in a compact metal shield case that shuts off external noise, and is inserted in a copier so that the window provided on the upper side of the sensor electrode surface faces the photosensitive drum surface.

Figure 1 Probe structure

Necessity for Surface Potential Sensing

In general, an electrostatic copier performs copying through the following process:

- Charging: Charges the photosensitive drum surface uniformly with the corona discharge from the charger.

- Exposure: The exposed area becomes conductive, and the electric charge of the surface escapes and disappears.

- Development: Obtains a visible image by making the charged toner adhere to the latent image.

- Transfer: Transfers the toner that has adhered to the photosensitive drum to the paper.

- Fixing: Dissolves the toner transferred to the paper by heat and fixes it.

- Cleaning: Removes the toner remaining on the photoreceptor and restores the initial condition after the transfer.

Needless to say, optimization of the toner amount that adheres to the photosensitive drum is the key factor for maintaining the best image quality at all times.

To that end, it is necessary to constantly maintain the charged state of the photosensitive drum at the default optimal value at the development timing in the above process 3). Therefore, the function that accurately senses the drum surface potential immediately after the cleaning process 6) and controls the charging (corona discharge) intensity in the process 1) becomes necessary. An overview of this function and control is shown in Figure 2.

Figure 2 Concept of surface potential optimizing control

The surface potential sensor (a) conveys the sensed surface potential level to the CPU as a voltage signal via the processing circuit, and (b) the CPU controls the high voltage generator, (c) to control the intensity of the corona discharge generated by the charger. In other words, even if changes caused by the environment or deterioration due to aging occur to the charging characteristic of the photosensitive drum surface, the charged state of the photosensitive drum can maintain the level that is optimized for high-quality image through the series of sensing-control processes described above.

As a matter of course, the factor that determines the capacity and reliability of this control system is the sensing precision and output stability of the surface potential sensor. However, due to the necessity to contribute to the enhancement of the copy speed, speeding-up of the sensor response is also required.

Superiority and Application Benefits of the EFS Series

In the EFS Series, the variation range of the sensor output (0 to 4.5V) is suppressed to ±0.05V or lower due to TDK's proprietary high-stability output circuit. Also, a sensing response speed of 11msec (typ.) has been achieved, which supports high-speed machines. Moreover, the available sensing distance has also been increased to 1.5 to 3.5mm. In this range, output voltage variation is small and a robust output stability can be obtained despite changes in the ambient temperature.

Surface Potential Sensing Mechanism

The relationship between the actuator and detection circuit that constitutes the probe is explained in the following using the model in Figure 3, in which the photosensitive drum surface is negatively charged.

On the sensor electrode surface inside the probe that faces the photosensitive drum surface with a distance of several millimeters, positive charge equal to the negative charge on the photosensitive drum surface (charge on the area that is cut off by the window and electric field line blocking shutters) is induced by the electrostatic coupling using air as the medium (the electric field lines in red in the figure).

When the driving voltage is applied to the piezoelectric element that has adhered to the chopper base in this state, the piezoelectric element extends or contracts in a longitudinal direction in this figure, and the electric field line blocking shutters at the end periodically open and close due to the flexure stress applied to the chopper.

Due to this regular open-and-close movement of the blocking shutters, the amount of electric field lines that pass through the window provided on the shield case of the probe, namely, the amount of charge induced on the sensor electrode surface, also increases or decreases periodically, which can be treated as an equivalent to a variable capacitor that periodically increases or decreases capacitance in the circuit. These changes are explained in a little more detail in the following.

Sensor Operation Model

A model explaining the movements of the electric field line blocking shutters is shown in Figure 4. The electric field line blocking shutters repeat the opening/closing movements, following the cycle of half open to fully open, fully open to half open, half open to fully closed, and fully closed to half open. The number of electric field lines connecting between the measured surface of the photosensitive drum and the sensor electrode also increase or decrease according to this cycle.

When looking at the series of changes described above in the "Sensing circuit model of the probe (Figure 3)" in the previous section, we can understand that the periodic potential variation induced on the sensor electrode surface by the opening and closing of the electric field line blocking shutters is causing movements of charges between the reference ground potential through the combined impedance of input capacitance Ci and input resistance Ri in the preamplifier for impedance conversion.

As a result, AC output Vo from the preamplifier is proportional to ground potential Ve of the measured surface of the photosensitive drum.

At this time, the following relationships are established between the chopper oscillation amplitude and the AC output from the preamplifier:

- When ground potential Ve of the photosensitive drum is fixed, the AC output from the preamplifier is proportional to the chopper oscillation amplitude.

- When the chopper oscillation amplitude is fixed, the AC output from the preamplifier is proportional to ground potential Ve of the photosensitive drum.

Therefore, the sensing precision depends on the stability of the chopper oscillation amplitude.

Stable Output Realized by Feedback Circuit

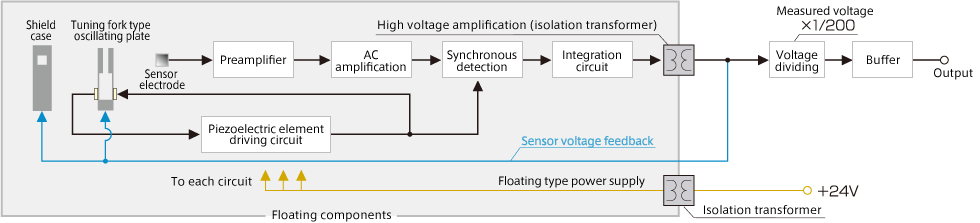

In order to overcome this basic challenge, TDK has applied its proprietary feedback circuit that gives the sensor non-electrode probe components the same potential as that measured by the sensor, so as to ensure stable sensing precision. The concept of this mechanism is described in the following, along with the flows shown in the circuit block diagram of Figure 5.

In this system, the probe voltage is cut off from the ground potential, and the detection signal extracted as an AC voltage from the preamplifier for impedance conversion is made to undergo AC amplification, synchronous detection, passing through an integrating circuit, undergoing high voltage amplification by an isolation transformer, and then being fed back as the probe standard potential.

Through this negative feedback, the detection signal is controlled to be as close to possible to zero, and the feedback voltage becomes equal to the measured voltage. In other words, the application of this proprietary circuit makes it possible to achieve highly reliable measured potential (feedback potential) that is not affected by variations in the chopper oscillation amplitude or sensing distance.

In addition, the high voltage output controlled to have the same potential as the probe value through this negative feedback operation is processed to 1/200th in the voltage dividing circuit (0 - 4.5 V) and output from the sensor through the buffer, and the variation range of this output is controlled to be ±0.05 V or lower.

Moreover, through the application of this high stability circuit, the sensing distance dependency and ambient temperature dependency of the output voltage, which could not be avoided in the conventional analog output type, have been resolved, and the world's highest class high stability sensing performance has been achieved, realizing the sensing distance between the photosensitive drum surface and probe sensor electrode of 1.5 to 3.5mm and the output voltage change with an ambient temperature changes from 0 to +50°C of 1% or less. Quick responsiveness of 11ms has also been achieved.