Gear Tooth Sensors PS-HR Series

Spread of FI System in Two-Wheeled Vehicles

As the transition to electronically-controlled fuel injection (FI) systems in automobiles and large two-wheeled vehicles rapidly progresses, their application in 250cc class light motorcycles (126 to 250cc), in which the application of fuel injection systems was said to be difficult from the perspective of both the complexity of the structure and cost, is also progressing, due to the reinforcement of regulations and trend of global standardization.

FI systems control the air intake amount, fuel supply amount, and fuel injection timing at an optimum level for each cylinder while processing information from various sensors in real-time. They eliminate the control limit of conventional carburetor systems, and have made it possible to control the air/fuel mixture and combustion at an almost ideal condition at any rotation ranges from low speeds to high speeds.

In addition, they are now capable of performing fine control such as optimization of fuel injection during start-up, low-speed driving, or acceleration and fuel cutting during deceleration or high-speed driving.

Environmental Design Required for Small Two-Wheeled Vehicles Under 125cc

Due to such progress of FI technology, environmental regulations that apply to two-wheeled vehicles are also taking a new step to reduce the existing acceptance emission limit targets by 30 to 60%, with the transition to the Worldwide-harmonized Motorcycle Test Cycle (WWTC).

In this new test cycle, small and medium-sized two-wheeled vehicles with an engine larger than 50cc but less than 150cc and a maximum speed of 50km/h or slower, or having an engine smaller than 150cc and a maximum speed faster than 50km/h but slower than 100km/h are categorized as "Class 1" vehicles that are subject to regulation and test cycle "Part 1" assuming urban area traveling is applied to these vehicles, and a strict reduction of CO, THC, and NOx emissions is required.

Reasons Why Inexpensive High-Precision Sensors are Demanded

In order to apply an FI system in a two-wheeled vehicle engine having an accelerator transmission mechanism that is delicate yet direct, elaborate manufacturing technology and detailed electronic control technology superior to those required for FI systems applied in large-sized automobile engines are required.

Moreover, for inexpensive 50cc class motorbikes or 125cc class small two-wheeled vehicles, the establishment of a rationalized design and mass production system that enables even further cost reduction will become essential, as well as further reduction of the size, weight, and power consumption of the FI system.

With the development of the next-generation FI technology with an eye to ever-progressing enhancement and expansion of environmental regulations advancing based on global consensus, advanced design and development results that can offer better precision and lower cost than the existing products are required for various sensors, which function as the eye of the FI system.

Approaches Made by TDK

TDK mass-produces gear tooth sensors featuring a proprietary rationalized structure design that simultaneously achieves world-class environmental resistance and high-precision sensing capability for ATVs (All Terrain Vehicles; four-wheeled buggy vehicles mainly used for agriculture, hunting, or leisure). They have been in wide use and have achieved a high reputation concerning their long-term reliable performance. An ATV is designed to withstand severe environments such as swamps, paddy fields, rough roads full of stones and pebbles, snowy road, and is equipped with robust environmental resistance that allows it to travel through a swamp thinly coated with ice in extreme cold at full throttle under high temperature conditions.

A gear tooth sensor plays an important role of transmitting the detected number of gears to the ECU for the speedometer display or switching between 2WD and 4WD. Since it is directly attached to the clutch unit of the ATV, it is exposed to severe environments similar to that of an engine, such as water submergence, shock from flying objects, or vibrations. Naturally, a robustness that far exceeds that of gear tooth sensors applied to automobiles is required for those applied in ATVs. TDK has established a unique domain in the development and mass-production system that offers advanced benefits in terms of the sensing capability and cost, while sufficiently fulfilling this requirement.

Sensing Method and Structural Advantages of the PS-HR92 Series Gear Tooth Sensors

TDK's PS-HR92 Series gear tooth sensors are the most advanced, direct coupler-connection-type models that have achieved unprecedented size and cost reduction, developed based on an environment resistant structure and noise resistant design technology verified in the ATV field in order to support the rationalized FI systems for 50cc class motorbikes or 125cc class small-sized two-wheeled vehicles.

The magnetic circuit design with an optimized layout of the high-sensitivity differential hall IC and magnet realizes zero-speed (ultra low-speed) rotation detection at high precision while suppressing jitter, even in the partial region such as during restarting after idling stops or when the throttle opening is small. In addition, owing to TDK's proprietary housing structure, the sensors have achieved excellent environmental resistance that accommodates temperatures from -30°C to +150°C while reducing cost, not to mention long-term reliability despite vibrations, wetting or flooding. The ratings and electrical characteristics of the PS-HR92 Series are shown in Table 1.

| Driving power supply voltage Vcc | 4.75 to 16V |

|---|---|

| Output circuit type | Open collector |

| Output voltage Vout | V HIGH > Vcc-05V/V Low ≦ 0.4 V |

| Output current Iout | 15mA max. |

| Duty ratio | 50±15%(depends on the gear shape) |

| Air gap | 2.0mm max.(depends on the gear shape) |

| Response frequency | 0 to 12kHz |

| Operating temperature range | –30 to +l50°C |

Applications

The PS-HR92 Series gear tooth sensors are best suited for speed sensors, cam angle sensors, or crank angle sensors for two-wheeled vehicles with a small displacement engine with FI system specifications. The Series also offers benefits far surpassing those brought by the conventional sensors of a similar type for emission reduction and designs that improve fuel efficiency and engine performance of medium- and large-sized two-wheeled vehicles that are categorized as WMTC "Class 2" and "Class 3", ATVS, and automobiles.

An example of application as a cam angle sensor is shown in Figure 1.

Figure 1 Application example of PS-HR Series gear tooth sensors (cam angle sensor)

The ECU calculates the ignition timing, fuel injection timing, and the injection amount for the FI system based on the detection signals sent from the cam angle sensor and the crank angle sensor.

To ensure the capabilities of the FI system with an enhanced emission control effect, such as optimization of the A/FI value, the precision and stable output of the sensor signals become an extremely important condition.

Advantages and Application Benefits, Environmental Resistance

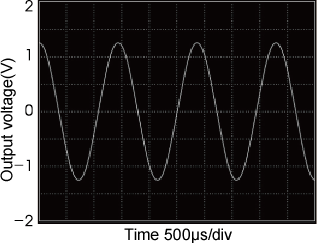

The features and advantages of TDK's PS-HR92 Series gear tooth sensors are summarized in the following. Table 2 is an example of performance comparison with a typical conventional analog type sensor using an electromagnetic pickup. The PS-HR92 Series digital sensors adopt a high-sensitivity differential hall IC. They output a high-precision and high level voltage waveform from zero speed to full throttle, even when the air gap is expanded to 2mm.

| Detection/Output Method | Digital type | Analog type |

|---|---|---|

| Operation Principle | Differential hall IC TDK differential hall IC type |

Electromagnetic induction (electromagnetic pickup) Typical product |

| Operating Temperature Range | –30 to +150°C | –30 to +150°C |

| Air gap | 2.0mm max.(depends on the gear shape) | 1.0mm max.(depends on the gear shape) |

| Detection Frequency | 0 to 12kHz | Refer to "Rotation speed - output voltage characteristic comparison example"(Figure 2) |

| Other | Capable of detection at zero speed rotation Resistant to surge noise |

Not capable of detection at zero speed rotation Susceptible to noise Requires a waveform shaping circuit |

Figure 2 shows a comparison example of the rotation speed - output voltage characteristic. When the output at the gear rotation speed of 500 rpm is 100% in the electromagnetic pickup type sensor, the output voltage drops with the decrease of the gear rotation speed, dropping down to as low as approximately 30% at 50rpm. It may cause malfunctions.By contrast, the output voltage ratio of the differential hall IC shows almost no change at all.

Figure 2 Comparison example of rotation speed - output voltage characteristic

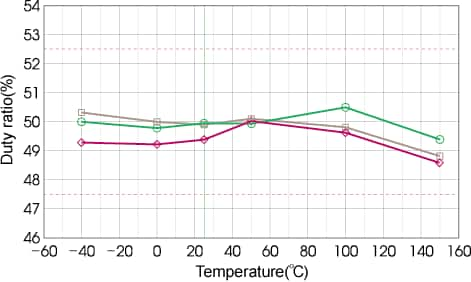

In addition, as is indicated by the environmental resistance list (Table 3) and the duty ratio-temperature characteristic example (Figure 3), the PS-HR92 Series sensors achieve excellent endurance under severer reliability tests, including heat shock endurance, shock resistance, and vibration endurance, not to mention support in a temperature range from -30 to +150°C. The sensors also realize the industry's top level long-term reliability with respect to water resistance, which is considered important in ATVs and two-wheeled vehicles, through TDK's proprietary seal structure.

| Vibration endurance | 50 to 2000 Hz (6 min./cycle), 20 hours, 294m/s2, 3 directions |

|---|---|

| Heat shock endurance | –30°C(30 min.) to 150°C(30 min.) x 500 cycles |

| Water resistance | JIS D 0203 S2 |

| High temperature operation | 500h at +150°C |

| Low temperature operation | 500h at –30°C |

| Transient voltage characteristics | JASO D001-94 (A-1, A-2, B-1) |

| Radioelectric field endurance | 100V/m、1 to 200MHz |

Figure 3 Example of duty ratio-temperature characteristic (air gap: 1.5mm/rotation speed: 50rpm/gear module: 2)

Detection Signal Reliability

Although an automobile wire harness uses relatively low voltage, in two-wheeled vehicles or ATVs, destructive surge noise often occurs as various control parts such as coils or relays that are driven by direct power supply from the battery.

In order to maintain high-precision sensing capabilities under such a severe electromagnetic environment, the PS-HR92 Series sensors incorporate a dedicated circuit that exhibits an excellent surge absorption capacity. They are equipped with robust noise resistance that satisfies the transient voltage characteristics JASO D001-94 (A-1, A-2, B-1), not to mention the radioelectric field endurance.

Detailed Design-In Design Support System

Efforts have been made to overcome various issues related to cost and structures for the introduction of the four-stroke FI system in engines of inexpensive two-wheeled vehicles, particularly 50 cc class motorbikes and 125 cc class small motorcycles. Enhancement of the system that can quickly and flexibly respond to such efforts is required for gear tooth sensors as well.

To be specific, a development environment that allows for quick optimization of design specifications of gear tooth sensors, such as the hall element layout of the magnetic field detection part, the shape of the internal magnet, or magnetic characteristics, for the gear shape and material of the detection target is desired. In the design-in system like this, TDK has established a powerful support system, fully utilizing abundant magnetic field simulation models based on our long-standing performance.

In addition, for models that are currently mass-produced, we offer a detailed improvement support system that is directly connected to the mass production line, including early detections of failure causes through magnetic field simulations or consideration and improvement suggestions of the gear shape, in cases where a quick response is required, such as failure occurrences. As a matter of course, we respond to each improvement request by our customers, such as jitter reduction or improvement of the sensing precision.