- Capacitors >

- Multilayer Ceramic Chip Capacitors

A.

Since the capacitance of BaTiO3 based capacitors changes with time, aging poses a unique problem for component manufacturers – that is, 'what is the capacitance of this capacitor?'

Like voltage and frequency test conditions, the industry has long recognized the aging issue and has determined a standard by which all capacitors should be measured*.

Simply stated the capacitance must be within the specified tolerance at 1000 hours age (or TOLH)5.

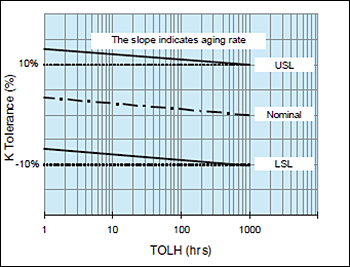

The capacitor manufacturer uses the material’s known aging rate and mathematically determines the capacitance tolerance limits for any point in time after deaging (see figures 3 and 4). The components are 100% electrically sorting with respect to its aging rate and TOLH. For example, a +/- 10% tolerance part may be sorted at +13/- 7% if the dielectric material’s aging rate is 3%. By utilizing this technique manufacturers can guarantee all capacitors to be within cap tolerance at 1000 hours based on TOLH.

Figure 1 : Example sorting limits for Class I material, K Tolerance

Figure 2 : Example sorting limits for Class II material, K Tolerance

NOTE : Because aging causes a decrease in capacitance over time, it is possible for the capacitance to be above the upper tolerance limit at times less than 1000 hours from TOLH, and less than the lower tolerance limit at times greater than 1000 hours from TOLH.

Immediately after soldering, adhesive setting, and other process accompanied by temperature rise, the capacitor is de-aged and the capacitance may not be within the tolerance. In some cases, it may be necessary to expand the tolerance range of the capacitance for in-circuit tests, taking aging of the capacitor into consideration.

*IEC-384-9 (1988), Appendix A

>>Multilayer Ceramic Chip Capacitors Product Site

For any other product-related questions or inquiries, please contact us throughone of our sales representatives or this website.