Ring Varistors as Motor Noise Solutions

TDK's ring varistor VAR-18 series use a strontium titanate semiconductive ceramic material whose electrical characteristics and physical performance are greatly improved compared to the conventional levels. This lineup covers a wide variety of shapes and dimensions as well as conventional sizes to meet various requirements. This flexibility and ease of use are great advantages for this lineup.

Guide on Ring Varistors as Motor Noise Solutions - Overview

What is a Varistor?

The term "Varistor" is coined from "variable resistor", meaning a component whose resistance value varies depending on the voltage. A high resistance value is maintained and almost no electric current passes until the voltage reaches a certain value (varistor voltage). When the voltage exceeds the value, the resistance value suddenly drops and a large electric current is allowed to pass. This property allows it to be used as a surge protection device to prevent circuit malfunction and destruction of an IC due to a surge of abnormally high voltage. For electronic devices, many disc type and multilayer chip type varistors are used. In DC motors with brushes, used for automobile components and the like, thin ring-shaped varistors are widely used for noise reduction and contact protection.

Role of Ring Varistors in Micro Motors

A ring varistor is attached to the commutator of a DC motor with brushes. The commutator is a device that switches current direction according to the rotation of the rotor. At the point of contact between the commutator and a brush, high surge voltage generated at the moment of switching current direction causes a spark, which leads to noise and wear of the brush. The ring varistor absorbs the surge voltage and prevents the spark (Figure 1).

Noise Countermeasure in Automotive DC Motors (1): Motor Noise Solution Offered by Ring Varistors

Ring varistors can be installed on DC motor commutators more easily and compactly and feature excellent noise absorption and control effects and contact protection effects. The planar electrode structure with electrodes formed on the surface of the ring-shaped varistor element allows for products with three electrodes, five electrodes, or other configurations according to the number of commutators. TDK offers the products with various numbers of electrodes and dimensions that can be adopted on nearly all compact DC motors including automotive DC motors.

Noise Countermeasure in Automotive DC Motors (2): Solution through a Combination with an MLCC with Dipped Radial Lead

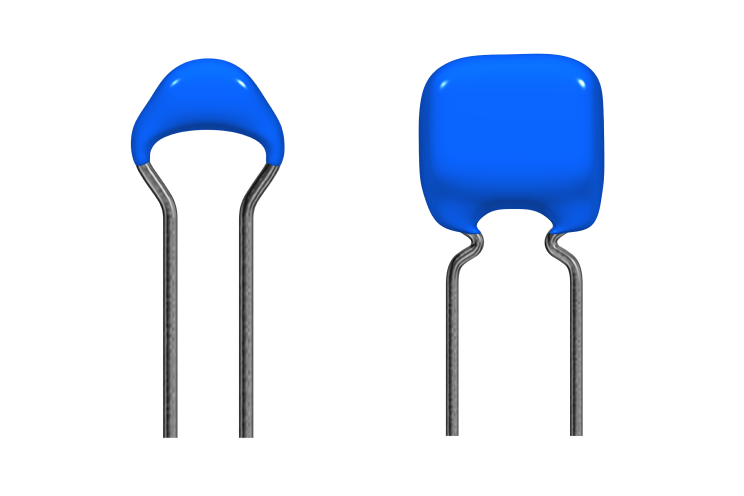

TDK also suggests more effective noise countermeasures for automotive DC motors through the combination of a ring varistor and another component. Capacitors are also used as noise countermeasures for automotive DC motors. For this purpose, MLCCs (multilayer ceramic chip capacitors) with dipped radial leads, which can be easily and surely connected by welding or swaging, are much more effective than standard MLCCs, which are soldered on a PCB. One of TDK's strengths is that we manufacture and provide both ring varistors and MLCCs with dipped radial leads. We offer solutions that meet the demands of our customers through our extensive product lineup.

As for lead capacitors, we offer a new halogen-free series, whose products exhibit very effective performance as countermeasures against acoustic noise, PCB deflection, DC motor noise, and the like.

Material and Characteristics of a Varistor

Special Semiconductor Ceramics Which Do Not Obey Ohm's Law

A pure resistive element obeys Ohm's law, V = RI (V: voltage, R: resistance, I: current). The current increases proportionately with the applied voltage and is represented as a straight line in a graph. However, some resistive elements do not obey Ohm's law and their resistance varies depending on the applied voltage. A varistor uses this characteristic. It absorbs irregularly generated high voltage such as surge voltage and ESDs (electrostatic discharges) and discharges them to the ground.The voltage-current characteristic of a varistor is approximated by the formula I =KVα. K is a constant and α is a voltage nonlinear coefficient (α coefficient). The coefficient α is 1 for a pure resistive element, but it is greater than 1 for a varistor. The larger the value is, the more the nonlinear voltage-current characteristic deviates from Ohm's law (Figure 2). Semiconductive ceramics such as ZnO (zinc oxide) and SrTiO3 (strontium titanate) are used as materials of varistors.

Noise Countermeasure in Automotive DC Motors (1): Motor Noise Solution Offered by Ring Varistors

Suppresses a Wide Range of Noise to Prevent Negative Impact on Automotive Electronic Devices

With recent improvements in safety and convenience, the number of small DC motors used in some automobiles has increased to over 100. An automotive DC motor may have a negative impact on an electronic device. For example, operation of the windshield wipers of an automobile may cause noise that can be heard through the radio. This is caused by a spark discharging at the point of contact between the commutator of a DC motor and a brush. The noise widely ranges from low frequency to high frequency. As a noise countermeasure in automotive DC motors, ring varistors, as well as components such as capacitors, are widely used, especially in small DC motors (Figure 3).

Features of TDK's Ring Varistors

With the VAR-18 series, TDK offers various ring varistors using a SrTiO3 (strontium titanate) semiconductor ceramic material. The main features and electrical and physical characteristics of TDK's ring varistors are explained below.

《Features and electrical and physical characteristics of the VAR-18 series, TDK's ring varistors》

●Combined surge absorber and bypass capacitor functions

SrTiO3 is a material that exhibits a high dielectric constant over a wide temperature range. By also providing varistor characteristics, excellent functionality can be demonstrated. It can function as a varistor against high voltage levels, such as surges, and function as a capacitor against lowvoltage noise to bypass and reduce the noise component. In other words, it has both the characteristics of a surge absorber and a bypass capacitor.

●Copper electrodes and a ceramic element with excellent heat resistance and flexure strength

TDK’s ring varistors are made with copper electrodes and ceramic elements with outstanding heat resistance. As a result, even if the soldering temperature is increased in order to use lead-free solder, there are no concerns regarding electrode erosion or thermal cracking. In addition, the ceramic elements have high flexural strength and is suitable for automated motor assembly.

●The temperature characteristic of the varistor voltage is positive

The temperature characteristic of a TDK's ring varistor is positive, which means that its resistance value increases as the temperature rises. This eliminates the risk of decreased varistor voltage at high temperatures and large currents flowing through the varistor as a result. There is no need to compromise noise reduction levels when setting the room temperature varistor voltage (E10 value) higher, which gives an advantage in design. Furthermore, it eliminates the problem of noise level being amplified at low temperatures and having a negative impact on the life of the motor.

●Excellent noise absorption and suppression across a variety of frequency bands achieved by optimal capacitance and α coefficient

For a small low-power DC motor, a ring varistor only measure is effective enough for suppressing high frequency radiation noise (Figure 4).

Noise Countermeasure in Automotive DC Motors (2): Solution through a Combination with an MLCC with Dipped Radial Lead

Mounted Easily and Securely in Small Spaces without Using PCBs

The combination of a ring varistor and an electronic component such as a capacitor realizes a more effective DC motor noise solution. Generally, as a noise countermeasure for electronic devices, SMD components such as MLCCs (multilayer ceramic chip capacitors) are used. However, using a PCB for mounting SMD components for an automotive DC motor causes various problems including space restrictions, increased costs, and deterioration of noise reduction effects due to wires. Components with lead wires are recently drawing attention as a way to resolve these issues.

SDM components soldered on automobile PCBs, which are used in inhospitable environments, are frequently exposed to thermal and mechanical stresses and have risks of solder crack, etc. On the other hand, components with lead wires can be easily and securely mounted in small spaces by welding or swaging. This ensures high reliability and may solve the problems of space restriction and costs. Components with lead wires have the advantage that they can be used without a PCB.

Figure 5 shows an example of a ring varistor and MLCCs with dipped radial leads mounted in a small DC motor. Two MLCCs with dipped radial leads are welded into a small brush holder. MLCCs with dipped radial leads are resin-coated. Thus they can meet requirements for weather resistance, moisture resistance, and the like.

Clears Requirements for CISPR 25 Class 5, an Extremely Stringent Noise Regulation

A DC motor emits two types of noise: conduction noise and radiation noise. As shown in the graphs in Figure 6, the combination of a ring varistor and MLCCs with dipped radial leads can greatly suppress both conduction noise and radiation noise, enabling compliance with CISPR 25 Class 5, an extremely stringent vehicle noise regulation.

In addition, motor units for systems such as a powertrain system and a driving and steering system are increasingly being placed inside engine compartments. Therefore, the need for electronic components that can withstand temperatures up to 150°C is increasing. TDK offers a lineup of various automotive grade products that can withstand temperatures up to 150°C, including MLCCs with dipped radial leads.

We Offer Both Ring Varistors and MLCCs with Dipped Radial Leads

Figure 7 shows application examples of ring varistors and MLCCs with dipped radial leads in automotive DC motors. With 30 to 40 mm as a threshold, ring varistors are used for smaller diameter motors and MLCCs with dipped radial leads are used for larger motors. As it is anticipated that noise regulations for automobiles will become more stringent in the future, it is widely expected that the combination of a ring varistor and MLCCs with dipped radial leads will be the motor noise solution. One of TDK's strengths, as an electronic component and device manufacturer, is that we produce both ring varistors and MLCCs with dipped radial leads. We can promptly provide optimal solutions satisfying customers' demands through our wide-ranging product lineup.

Guide on Motor Noise Solutions Offered by Ring Varistors - Conclusion

TDK's VAR-18 series ring varistors use a strontium titanate semiconductive ceramic material whose electrical characteristics and physical performance are greatly improved compared to conventional levels. They are simple, easy, and effective protection devices attached to the commutators of DC motors with brushes, such as motors for automobile components, that can prevent noise generation and wear. For the improvement of safety and convenience, noise regulations for automobiles are anticipated to become more stringent in the future. The combination of a ring varistor and MLCCs with dipped radial leads enables compliance with CISPR 25 Class 5. Please take advantage of this excellent performance in your products.

Main features, applications, and characteristics of the VAR-18 series, ring varistors for micro motors

【Main Features】

- Use a semiconductor ceramic material consisting mainly of SrTiO3 (strontium titanate)

- Employ copper electrodes and a ceramic element with improved heat resistance

- Ceramic element has excellent flexure strength and is suitable for automated motor assembly

come in a wide range of dimensions appropriate for almost all motors

【Main Applications】

- Noise countermeasure and contact protection for micro motors, including automobile DC motors

【Main Characteristics】

- The temperature characteristic of the varistor voltage (E10 value) is positive

- Noise level not amplified at low temperatures and no negative impact on motor life

- Varistors have a large capacitance, like conventional varistors, and excellent functions to eliminate and control noise in high frequency bands

Product lineup of VAR-18 Series, ring varistors for micro motors

| Diameter Symbol | Dimension (mm) | Number of electrodes | ||

|---|---|---|---|---|

| ΦD1 | ΦD2 | T max. | ||

| 042 | 4.2±0.15 | 2.8+0.2,-0.1 | 0.60 | 3 |

| 048 | 4.8+0.1,-0.2 | 3.5+0.2,-0.1 | 0.60 | 3 |

| 060 | 6.0±0.2 | 4.0+0.2,-0.1 | 0.70 | 3 |

| 080 | 8.0±0.25 | 5.0±0.15 | 0.85 | 3 |

| 085 | 8.5±0.3 | 5.8±0.15 | 0.75 | 3 |

| 094 | 9.4±0.3 | 5.78±0.15 | 1.05 | 3 |

| 107 | 10.7+0.2,-0.35 | 6.7+0.25,-0.1 | 1.10 | 3 |

| 120 | 12.0±0.3 | 6.95±0.15 | 1.10 | 5 |

| 160 | 16.0±0.4 | 9.4±0.3 | 1.70 | 5 |

| 230 | 23.0±0.5 | 15.0±0.5 | 2.00 | 7 |

■PERFORMANCE

| Operating temperature range | -30 to +85(℃) |

| Pulse resistance | ΔE10,Δα10±15(%) |

| Moisture resistance [60±2℃, 90~95%RH, 240h] | ΔE10,Δα10±10(%) |

| Soldering heat resistance [Within ΔT290℃, 3s] | ΔE10,Δα10±10(%) |

| Flexure strength | Accorfing to individual specifications. |

| Electrode tensile strength | Accorfing to individual specifications. |

■Varistor Voltage Temperature Characteristics

【VAR-18 Series, ring varistors】 Product Information and Sample Purchase

*Please select the type and size suitable for your applications to improve the reliability of your products.