- Capacitors >

- Multilayer Ceramic Chip Capacitors

A. Any number of things can cause this problem, however the most common are solder joint quality and harsh handing. Solder joint quality here means the solder fillet volume and its coverage on the component’s termination.

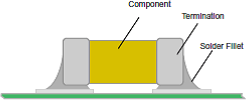

Figure 1: Side view of soldered component

The adhesion between the component and the PCB is directly proportional to the amount of solder used in most cases.

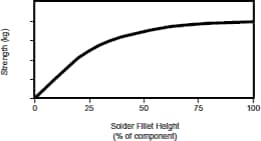

Solder fillets typically become smaller as the component becomes smaller, and the lack of solder mass will reduce the adhesion strength also.

Figure 2: Terminal adhesion increases with solder amount

Figure 3: Solder amount increases with case size increase

Abusive handling obviously can cause the capacitors to come off after soldering, but even normal handling can dislodge a component from the PCB with small solder fillets. Touching the populated PCB with the hand or instrument should be a point of training and minimized as much as possible. Also, aqueous washes offer use higher water pressure than necessary when cleaning flux from the board. Brushes, conveyors, and robotics are all areas of handling risk.

>>Multilayer Ceramic Chip Capacitors Product site

For any other product-related questions or inquiries, please contact us throughone of our sales representatives or this website.