NTCWS series: Wire Bondable NTC temperature sensor

Among them, a semiconductor laser that is positioned as an important component requiring a temperature sensor to keep the ambient temperature constant. A thermocouple can be used as a temperature sensor, but the NTCWS series of NTC thermistor is more suited to this application.

The NTCWS series can be mounted by wire bonding, achieving small size, high accuracy and unquestionable reliability.

Contents

Regarding the NTC Thermistor

The NTC (Negative Temperature Coefficient) thermistor is a semiconductor ceramic in which resistance decreases logarithmically with temperature rise.

It is widely used as a temperature sensor in every field where temperature detection is required, including automobiles, industrial equipment, home appliances, and medical devices. Please see the page linked below for more details.

Outline of the NTCWS-series Products

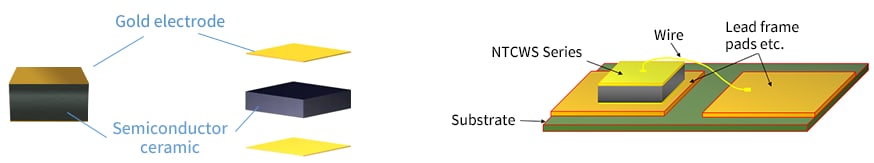

The NTCWS series are a type of NTC thermistor in which gold electrodes are terminated on the upper and lower surfaces of the ceramic.

These products are characterized by a high degree of freedom in installation location because they can be mounted by wire bonding.

In addition, they have a wide operating temperature range of ‐40°C to 125°C, exhibiting excellent performances at high-temperature

Product Lineup

The NTCWS series have three developments of resistance value characteristics as described below. The resistance tolerance can be selected among ±1% and ±3%.

Please contact us separately if you are looking for other resistance value characteristics.

| Operating temperature |

-40 ~ 125 ℃ |

|---|---|

| Figure |  |

| Electrode | Au (Thick film) |

| Package | 2 inch tray (400 pcs/Tray) |

| Part No. | R25 (KΩ) |

R25 Tolerance (%) |

B25/85 (K) |

B25/85 Tolerance (%) |

Dimensions (mm) |

|---|---|---|---|---|---|

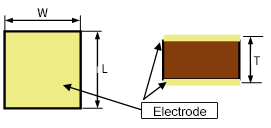

| NTCWS3JF103FC1GT*** | 10 | ±1 | 3410 | ±1 | L,W:0.48±0.04 T:0.25 max |

| NTCWS3JF103HC1GT*** | ±3 | ||||

| NTCWS3UF103FC1GT*** | 10 | ±1 | 3930 | ±1 | L,W:0.33±0.04 T:0.25 max |

| NTCWS3UF103HC1GT*** | ±3 | ||||

| NTCWS4AF104FC1GT*** | 100 | ±1 | 4050 | ±1 | L,W:0.31±0.04 T:0.25 max |

| NTCWS4AF104HC1GT*** | ±3 |

Product Features

1. High accuracy

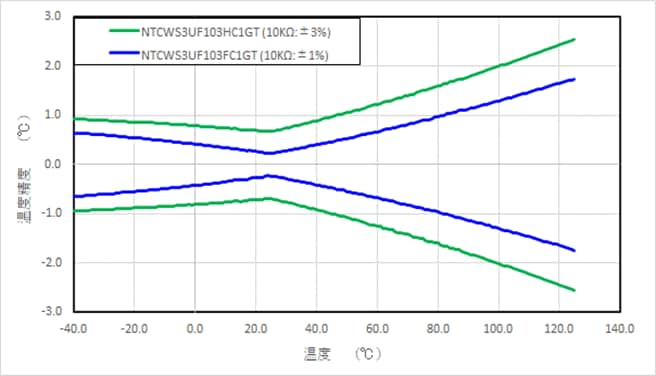

The NTCWS series have a lineup of narrow-tolerance products with a resistance tolerance of ±1%. The temperature accuracy at 25°C is ±0.3℃ for 1% tolerance and ±0.7℃ for 3% tolerance.

2. High reliability

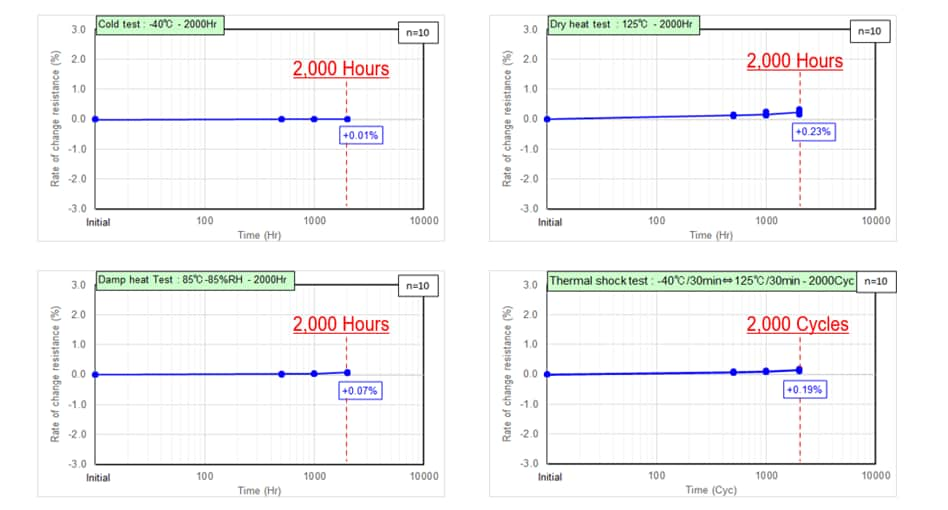

The NTCWS series have achieved high reliability in any environment. For example, the Dry Heat Test is a rigorous test in which a product is left in an environment of 125°C for 2000 hours with the resistance value change rate of only +0.23% after 2000 hours.

In addition, the Thermal Shock Test test condition is left alternately at low temperature (-40℃) and high temperature (125℃) for 30 minutes each with the resistance value change rate of +0.19% after testing 2000 cycles.

"Example of reliability:(NTCWS3UF103FC1GT:R25=10KΩ±1%、B25/85=3930K±1%)"

Reference: Telcordia GR468

Example of Application

The NTCWS series are utilized for applications such as temperature detection near the laser diodes for optical transceivers in the optical communication sector, LiDAR in the automotive sector, and power semiconductors in the industrial equipment sector.

Apart from these, the series are ideal for applications where a temperature sensor needs to be wire bonded.

Temperature detection near the laser diode for an optical transceiverA laser diode that is used in an optical transceiver stabilizes the temperature around the laser using a temperature sensor in order to output laser light having a stable wavelength.

Power Semiconductor Temperature DetectionAmbient temperature needs to be controlled for a power semiconductor that is used in a power module, including IGBT, in order to prevent overheating. In addition, a temperature sensor that can be mounted by wire bonding is required, because a method for mounting peripheral components is wire bonding.

LiDARThere are various methods for LiDAR, which is attracting attention along with the automation of driving.

Among them, a temperature sensor is utilized for LiDAR with a semiconductor laser so that the temperature around the semiconductor laser is controlled.