Energy Harvesting: the TDK combination of Solar Cells and CeraCharge

Usually the power is stored as electricity.

Batteryless and Wireless can realize less waste. No battery replacement and recharging save labor and cost.

They contribute for sustainable society and improve corporate value.

Contents

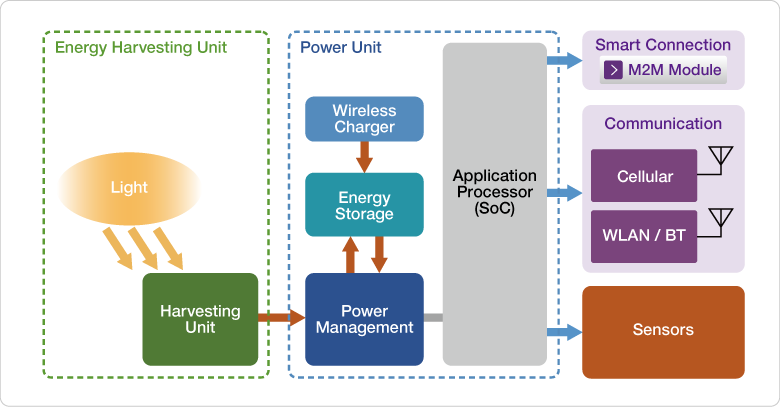

Energy Harvesting - System architecture

There are different architectures possible defined by the applications power demand and safety requirements.

TDK offers an extensive range of electronic components for Energy Harvesting application's.

The TDK complete solution includes Harvesting Unit (Solar Cells) plus the Energy Storage (CeraCharge).

in addition several Sensors and others Passive Components.

Table 1: Wireless Sensor Module with Energy Harvesting (Example1)

Harvesting Unit

Energy Storage

Wireless Charger

Power Management

Target Applications

The Internet of Things (IoT) has already transformed society in areas including smart homes, wearables, medical devices, manufacturing, infrastructure, and transportation. There are currently billions of connected IoT devices,

Delivery of sufficient power and energy to autonomous systems is a key requirement for their success.

From simple gadgets to complex devices for the industrial IoT – they all require compact, reliable and extremely safe power supplies.

Target applications:

Wearable devices

Wearable devices Beacons

Beacons Wireless Sensor Node

Wireless Sensor Node Condition based Monitoring(CbM) with Various Sensors

Condition based Monitoring(CbM) with Various Sensors IoT terminal power supply

IoT terminal power supply Smart card

Smart card Smart lock

Smart lock Energy harvesting (environmental) power generation element

Energy harvesting (environmental) power generation element Charging endowing other electronic devices

Charging endowing other electronic devices Power backup, such as real time clocks

Power backup, such as real time clocks Energy storage for energy harvesting devices

Energy storage for energy harvesting devices Sub battery for smoothing voltage and current

Sub battery for smoothing voltage and current

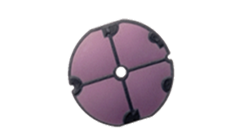

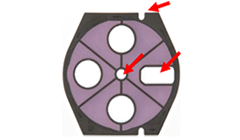

Solar Cells

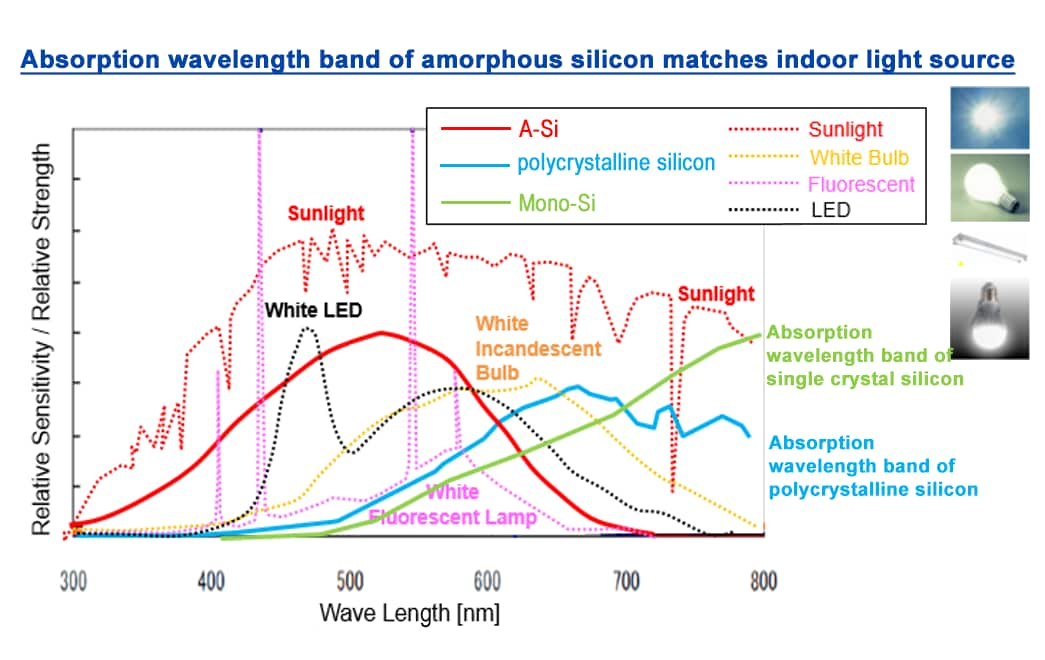

TDK Solar Cells (BCS series) are thin, lightweight, flexible, amorphous silicon-type film solar cells in circular or quadrangle shapes. The BCS Solar Cells offer high power generation efficiency under fluorescent lamps and LED light sources with output stability in low and dim light conditions. These solar cells help reduce the cost of battery replacement and wiring while extending the life of the primary battery and the usage time of rechargeable devices. There is no equipment damage or environmental pollution due to liquid leakage. The clean-energy BCS Solar Cells from TDK are suitable as a power source for indoor products.

Features

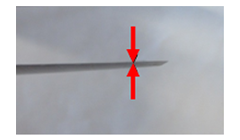

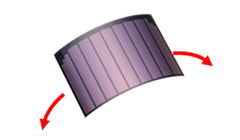

- - Thin, lightweight, and flexible solar cells adopting a film substrate.

- [Approx. 0.1g (depending on size) / 0.2 mm or less].

- - It has high power generation efficiency under fluorescent lamps and LED light sources, and is suitable as a power source for products used indoors.

- - There is output stability in low light and dim light.

- - Can be custom-designed according to various shapes and applications.

Advantages of Solar Cells

- - It reduces the cost of battery replacement and eliminates the hassle.

- - Reduce the cost of electrical wiring.

- - Extends the life of the primary battery. (When combining primary batteries).

- - Extend the usage time of rechargeable devices.

- - There is no equipment damage or environmental pollution due to liquid leakage.

- - It contributes to improving the image of products by using clean energy.

- - It improves Corporate value to focus on SDG

TDK amorphous silicon film solar cell

~ Light Weight, Thin Thickness, Mechanical Flexibility ~

| TDK Solar Cell: | Light Weight | Thin Thickness | Shape Variations | Mechanical Flexibility |

|---|---|---|---|---|

| Weight Comparisons (Diameter: Ø30mm) |

Thickness | Shape | Sheet Bending Capability | |

| 0.1g | 0.2mm | Capable to make Notches, Slits, Holes, Windows | Ø20mm |

Install in thin, narrow, small space

Geometrical design free

Put on curved surface

| TDK Parts Number | Device Size | Thickness (Electrode) |

Thickness (Other) |

Individual weight | Cells in Series | Output @ 200Lx | ||

|---|---|---|---|---|---|---|---|---|

| Operating Current | Operating Voltage | Open Circuit Voltage | ||||||

| BCS4630B9 | 46x30mm | 0.18mm | 0.15mm | 0.20g | 9cells | 19μA | 3.8V | 6.3V |

| BCSC241D4 | φ17mm | 0.18mm | 0.15mm | 0.03g | 4cells | 7μA | 1.5V | 2.8V |

| BCSC451B2 | 25x19mm | 0.18mm | 0.15mm | 0.07g | 2cells | 30μΑ | 1.0V | 1.4V |

| BCSC452B3 | 0.07g | 3cells | 19μA | 1.5V | 2.1V | |||

| BCS2717B4 | 27x17mm | 0.18mm | 0.15mm | 0.07g | 4cells | 16μA | 2.0V | 2.8V |

| BCS2717B6 | 6cells | 10μΑ | 2.6V | 4.2V | ||||

| BCS1714B4 | 17x14mm | 0.18mm | 0.15mm | 0.04g | 4cells | 7.8μA | 2.0V | 2.8V |

| BCS1714B6 | 6cells | 5.0μA | 2.6V | 4.2V | ||||

| BCS4430B6 | 44x30mm | 0.18mm | 0.15mm | 0.20g | 6cells | 30μΑ | 2.6V | 4.2V |

| BCSC491B6 | ||||||||

CeraCharge™ - Rechargeable SMD Solid-State Batteries

CeraCharge™, the world’s first Rechargeable SMD Solid-State Batteries, is a new technology that meets all these demands.

Life today would be unimaginable without batteries and accumulators using a wide variety of technologies and with widely differing capacities. The Internet of Things in all its facets will in future require billions of special power supplies tailored to the requirements of new ultra-low-power semiconductors and sensors. These devices must function for years, independently of external power supplies, by using energy-harvesting technologies. The demands made on energy storage media are as follows: small dimensions, rechargeability, intrinsically safe, easy to assemble, low cost and long service life. Not all of these requirements can be met simultaneously using currently available technologies. For many applications, the TDK CeraCharge now offers a way out of this dilemma. Unlike most common technologies, this involves a solid-state rechargeable battery with no liquid electrolyte through which the lithium ions move during charging or discharging. CeraCharge is based on a multilayer technology, similar to MLCC.

Thanks to this technology, a relatively high energy density and smallest volume are combined with the safety and high volume manufacturing benefits of ceramic multilayer components. In addition, the use of a solid ceramic electrolyte rules out the risks of fire, explosion, or the leakage of liquid electrolyte.

Simple process thanks to SMT-compatible design

CeraCharge is the world’s first rechargeable battery to be designed as an SMT-compatible component. Accordingly, this results in further advantages such as easy placement of components and the use of conventional reflow soldering processes, which in turn reduces the production costs of the devices using CeraCharge. Initially, the CeraCharge is available in an EIA 1812 package (4.5 mm x 3.2 mm x 1.1 mm). This component offers a capacity of 100 µAh at a rated voltage of 1.5 V.

Features

- ◼ Rechargeable, long life/cycling time for energy storage and supplying devices.

- ◼ All-ceramic-structure, eliminating the risks of explosion, burning, and leakage of liquids.

- ◼ SMT compatible chip, Pb-free reflow solderable.

- ◼ RoHS compatible.

- ◼ Li-based ceramic oxide electrolyte / electrode and copper charge collector.

- ◼ Sputtered Cr/Ni/Ag terminal electrodes.

Advantages of CeraCharge

- - No liquid electrolyte; no burn, no leak, no explode.

- - 1000 cycles, after that, at least 80% of capacity remains.

- - Any number of individual components can be easily connected in series and/or parallel to increaser capacity.

- - No special handling required for recycling.

- - Wide operating temperature usage.

- - Suitable for vacuum applications

- - In mass production (LT 8 Weeks)

Rechargeable Multilayer Ceramic Chip Battery

Series/Type:

Ordering code:

BCT1812M101AG

B73180A0101M062

General technical data

| Nominal voltage | 1.5 | V |

| Typical operating voltage Vop1) | 0... 1.6 | V |

| Maximum charge voltage1) | 1.8 | V |

| Nominal capacity2) | 100 | μАh |

| Nominal discharge current | 20 | μА |

| Operating temperature | -20... +80 | °C |

1) It is recommended to operate below 1.6 V. In case cycle lifetime degradation is acceptable, it is also possible to charge up to 1.8 V.

2) At ambient condition 25 °C and relative humidity less than 60%