Sensors for New Mobility

Contents

Electrification and the impact on sensors

As carmakers move away from the internal combustion engine (ICE) toward hybrid and battery-driven designs (xEVs), the sphere of deployment that sensors occupy within these designs is expanding. According to IHS Markit, the number of distinct xEV models will likely increase from the current figure of about 335 to 800 by 2030. Legislation, government incentives, and improved charging infrastructures provide additional stimulus. Carmakers must establish industrial partnerships within a relatively short time frame to successfully incorporate these new sensor technologies into their designs. TDK's unified sensor portfolio offers a comprehensive suite of sensors perfectly suited for automotive applications. The portfolio encompasses both the traditional ICE and the expanded xEV requirements. These include:

| Temperature | Pressure | Angle | Speed | Torque | Current | Microphone | Motion/inertial | Hall switch | Embedded motor control solutions | Gas | Touch |

Within a vehicle, closed-loop feedback mechanisms exist to monitor and control mechanical, electronic, or electromechanical processes. The sensor, or a combination of sensors, produces the input to such systems, providing data relating to the process it is monitoring. This data could be in the form of rotational data in the case of wheels, axles, and motors, for instance. Other feedback systems within a vehicle control temperature, current flow, and pressure. Here, specific or combinations of sensors (sensor fusion) provide the relevant measurement data.

TMR Sensors

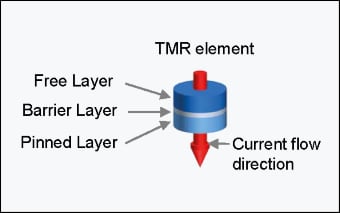

Tunnel magnetoresistance (TMR) sensors have multiple applications within a vehicle. They can be used to detect steering wheel torque or angle, motor/axle position, 'eCaliper' braking systems, and wiper actuation. The TAS series of TMR sensors feature high output, low power consumption, good angular accuracy, and low temperature drifts. The TMR element is made up of three layers: A fixed magnetic layer and a free layer, separated by a barrier layer (made of a thin insulator). The magnetization of the free layer changes with the external magnetic field it is exposed to. When the magnetic field of the two layers is aligned, the electrical resistance of the element is low. Conversely, the resistance is high when the magnetic field of the two layers is in opposition.

Hall Sensors

Hall sensors detect the resultant voltage differences that flow within a semiconductor when a magnetic field is applied perpendicular to it. In this way, the Hall switch compares the measured magnetic field strength to a predefined level, or a level programmable in the sensor. Once this level is exceeded (the switching point), the output of the sensor changes. TDK offers both programmable and fixed options within their Hall switch families. Hall switches can be used, in combination with a permanent magnet, to indirectly measure variables such as rotation, speed, distance, pressure, angle, and fluid levels. TDK’s 3D HAL® pixel-cell technology is the core of the HAL 39xy direct angle sensors for multidimensional magnetic field measurement. These sensors accurately measure magnetic fields while being insensitive to stray fields. The unique concept is based on an array of Hall plates. The programmable 3D position sensors HAL 3930, for instance, feature an in-built PWM/SENT or SPI interface.

The thermal management of batteries, charging circuits, and drive train components in xEVs is a prime example of the expanded sphere in which sensors play a pivotal role.

For the maximum range of electric vehicles, the critical components of the drive train have to operate in different temperature ranges. The battery requires much lower temperatures than the power inverter does, while the magnets in the motor lose their strength when it’s hot. For cooling down, up to eight LIN bus controlled electronic valves direct the cooling liquid to these components. These valves can be controlled by the embedded motor controllers HVC 4223F together with the 3D position sensors HAL 3930. While the HVC 4223F directly drives the actuator motors, HAL 3900 provides position feedback to close the control loop.

Temperature Sensors

Temperature sensors must analyze accurately and react quickly to fluctuations in these areas to avoid thermal runaway and subsequent fire risk. The high currents that flow when driving or charging a BEV can be such that a slight increase in contact resistance within a connector can manifest as a devastating temperature rise within it (Pv = I2 R). TDK has developed a temperature sensor that mounts directly in the connector between the vehicle battery and inverter. This hot spot is the area most likely to heat up during high current flow.

The NTCG series and B57xxxV5 series of sensors are packaged in a robust and versatile housing designed to form part of the core of the connector. The sensor features a negative temperature coefficient (NTC) element mounted within a ceramic husk, offering a high operating temperature and high electrical insulation. Positioning the sensor in this way optimises the speed with which it can sense any temperature fluctuations. This, in turn, allows the charging or drivetrain circuits to react quickly and mitigate temperature increases by limiting the currents flowing through them.

Pressure Sensors

Pressure sensors, such as the C43/C44 series, that measure the pressure within the lithium-ion cells are an equally important feature in the xEV battery management system (BMS). They keep track of working pressures and report abnormal pressure increases to the BMS. The response times of such sensors can detect and report pressure increases within a cell arising from a thermal event more quickly than temperature sensors alone.

On the road to autonomous driving

In addition to the seismic shifts in car design that the transition to e-mobility represent, advanced driver assistant systems (ADAS) are evolving in terms of reliability and functionality as they progress toward higher levels of driving autonomy. Sensors are pivotal to the integrity of such systems, often working in combination (sensor fusion); they give the system a reliable, accurate, comprehensive view of a vehicle's surroundings. These systems are subject to vehicle vibration, and their outputs benefit from electronic stabilisation. Using an inertial measurement unit (IMU), such as the IAM-20680, compensates the system from extraneous vibration and improves its results accordingly. By improving the quality of the images produced by the various sensing elements, LIDAR, radar, and cameras, the system's accuracy can be enhanced. IMUs also provide accurate location data for V2V vehicle-to-vehicle systems and infrastructure. Additionally, using IMUs enhances positioning systems in cases of dead reckoning, for example travelling under a tunnel or in a densely populated city. Here, conventional GPS/GNSS signals may be unavailable or unreliable.

The in-cabin experience of the digital cockpit

The use of sensors and electronics within the cockpit all serve to enhance the comfort, security, and safety of the occupants. Seats can automatically adjust for different drivers, wipers automatically come on when it rains, and lights come on when it is dark, or the car is in a tunnel. The high-quality IMU stabilizes visual images from reversing cameras, improving the driving experience as well as the accuracy of the ADAS. All of these advanced sensor-based systems serve to improve driver concentration by limiting distractions.

The human-machine interface (HMI) between driver and machine is changing. Voice commands, gesture control, and haptic responses form part of this new interface in the digital cockpit. As we progress toward higher levels of autonomy, new technologies spearhead alternative notification and control mechanisms within the cabin. TDK provides a range of MEMS motion sensors and microphones in their SmartAutomotive™ range, specifically designed and tested for the automotive market. MEMS microphones eliminate road noise through Road-noise Active Noise Control (RANC) and improve the reliability of voice-activated systems.

Piezo actuators,PowerHap, convey tactile sensations to drivers, also known as haptic feedback, which is a technology increasingly used in vehicle touch displays. It enhances the sense of realism when using infotainment functions, such as digital buttons and other controls, for more reliable operability. In addition to touch technology where the driver can be distracted by looking at the display, is gesture control using ultrasonic sensors.

Summary

The role that electronic devices and sensors play in modern vehicle designs is expanding rapidly. Electric vehicles require responsive current and temperature control in their charging and drivetrain circuits, opening a new realm of sensor deployment.

TDK offers a full suite of sensors suited for automotive applications combined with deep expertise to offer guidance and assistance to aid carmakers and tier 1 suppliers with implementation. TDK strives to form constructive partnerships and welcomes enquiries in this regard from those looking to improve the performance of current sensor applications or devise sensors for new applications, or both.