Application NoteSensors Enhance Engine Intake and Exhaust Performance

- Click here for the Temperature Sensor (NTC) Product Portal

- Click here for the Pressure Sensor Die Product Portal

At the same time, measures to reduce CO2 and exhaust emissions by addressing environmental issues require efforts to develop engines with higher efficiency.

In this article, we present TDK temperature sensors (NTC thermistors) and pressure sensor transmitter/pressure sensor die products that are essential for enhancing engine intake and exhaust performance in order to contribute to the resolution of these issues.

Contents

Engine Management Systems that Seek to Raise Efficiency

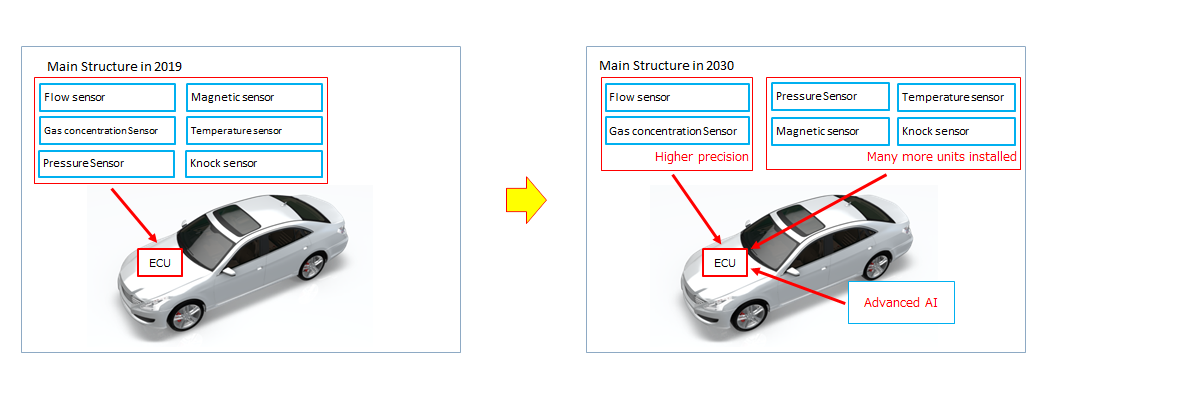

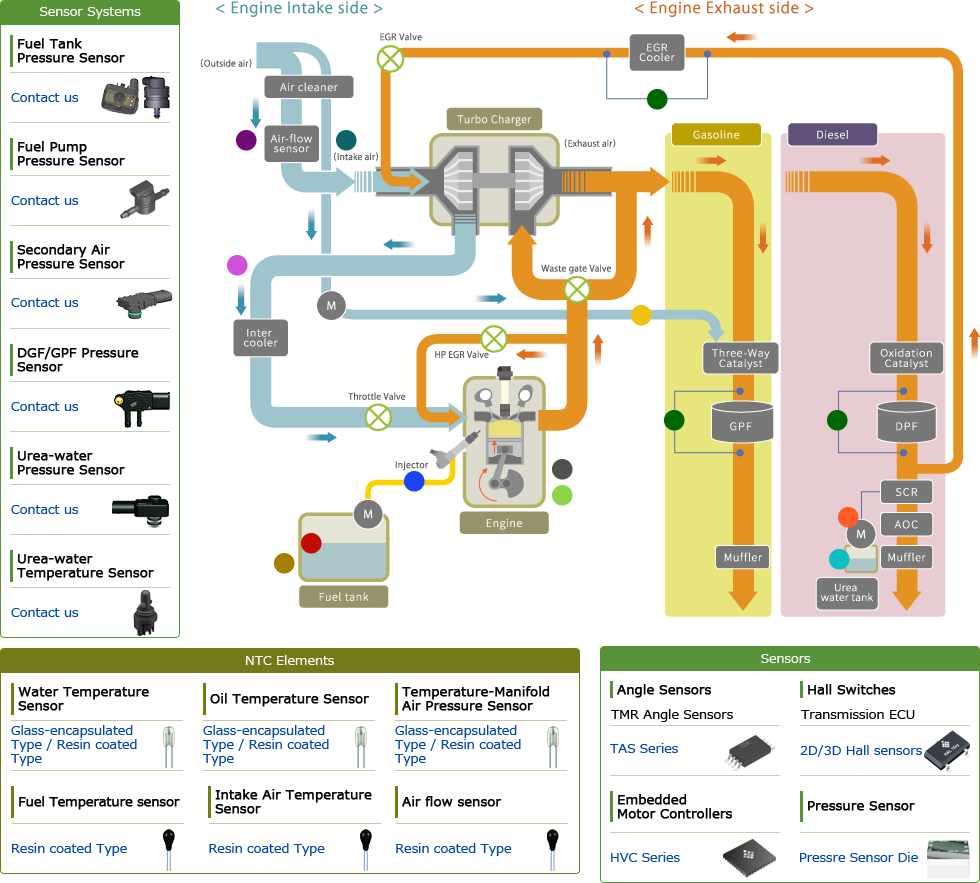

Both gasoline and diesel engines use various sensors (flow sensors, gas concentration sensors, NOx sensors, PM sensors, etc.) and actuators (injectors, throttle valves, EGR valves, etc.) as engine management systems to raise engine efficiency and comply with environmental laws and regulations (fuel efficiency standards and emission standards). Advances in engine management systems are made by improving algorithms that increase sensor and actuator sensitivity and responsiveness and by developing compliant processes (Figure 1). The intake and exhaust system temperature sensors (NTC thermistors) and pressure sensor transmitter/presser sensor die products provided by TDK play important roles in this process (Figure 2).

Intake and Exhaust System Temperature Sensors (NTC)

NTC elements used in automobile exhaust systems can be used as water temperature sensors, oil temperature sensors, temperature manifold air pressure sensors, fuel temperature sensors, intake air temperature sensors, and airflow sensors. TDK’s NTC thermistors have high sensitivity and excellent long-term stability. A diverse selection of products is available and can be used for a wide range of applications. Glass sealed type products have a very short response time due to the compact design. Epoxy resin sealed types have excellent moisture resistance and high accuracy and support a wide temperature range.

Overview of Temperature Sensor (NTC) Element Products

Features

- The glass sealed axial lead structure provides excellent resistance to high-temperature, high-humidity

- Variation in resistance temperature characteristics is kept low.

- The application of semiconductor mass production technology provides excellent miniaturization and mass production characteristics as well as high cost performance.

- Lead wires can be bent according to the mounting conditions.

- An epoxy coating is available to improve weather resistance and reduce stress on the glass components.

| Glass-encapsulated | Resin coated | Bondable | |||

|---|---|---|---|---|---|

| Type | Radial lead | Axial lead | Mini sensor | Under development | Chip |

| Picture |  |

|

|

|

|

| Type (Part No.) |

G15*0/G15*1 (B575*0G1*/B575*1G1*) |

NTCDS/NTCDA /NTCDE/NTCDZ |

S864 (B57864S*) |

L862 (Under Development) |

S860 (B57860S*) |

| Feature |

|

|

|

|

|

| Temperature range | -40 °C to 300 °C | -40 °C to 250 °C | -55 °C to 155 °C | -55 °C to 155 °C | -40 °C to 150 °C |

| Lead wire |

|

|

|

|

|

| Package | Bulk, Stripe | Bulk Ammo packing |

Bulk | Bulk, Stripe | On tape (on 8-inch frame) |

Pressure Sensor Transmitter/Pressure Sensor Die Products for Intake and Exhaust Systems

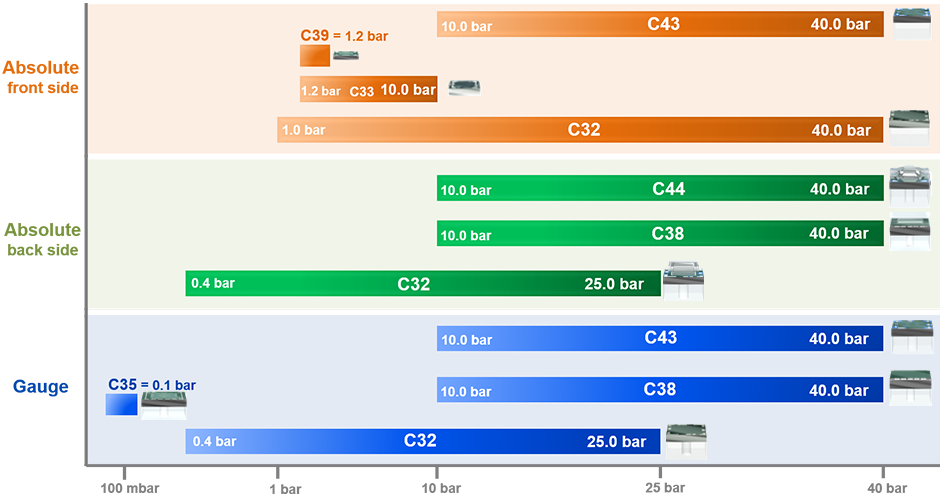

Pressure sensor transmitters used in automotive exhaust systems have embedded pressure sensor dies. In fuel control systems, these products can be used as fuel tank pressure sensors, pump fuel pressure sensors, secondary air suction depression sensors for the intake system, differential pressure system between the diesel particulate filter (DPF) and gasoline particulate filter (GPF) in the exhaust system, and urea water pressure sensor. Long-term sensor stability and high-precision pressure sensing are essential in order to meet the requirements of modern systems in terms of increasing automobile fuel efficiency and reducing harmful emissions.

Overview of Intake and Exhaust Pressure Sensor Die Products

High sensor accuracy is achieved through integrated in-house wafer manufacturing, adjustment, and packaging. These products have excellent robustness and can output stable signals over extended periods.

- Outstanding environmental resistance

- Wide temperature operating range

- Both analog and digital (SENT) output are supported

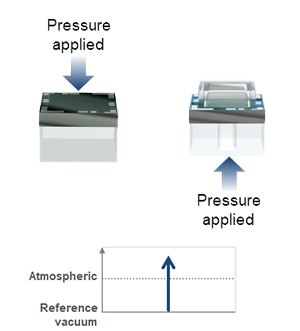

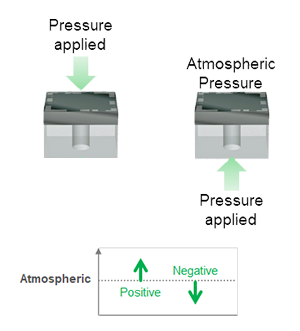

These are custom products manufactured according to required customer specifications.Please inquire concerning the details.Figure 5 shows an embedded TDK pressure sensor die compatible with various formats used to create these products.

| Absolute | |

|---|---|

| Gauge | Differential | |||

|---|---|---|---|---|

Summary

Tremendous advances are being made in improving fuel efficiency and reducing emissions, regulations are being made tighter on a global scale. In order to respond to and resolve these issues, the TDK Group remains committed to contributing to the automobile society while making advances in the expertise it has accumulated through many years of delivering products and the technologies that it has refined. Detailed information on each product can be found at the Product Center on this site. Please contact TDK for specifications and other information on individual products.

Contact Information

Related Links

Product Portal

- Sensor Solution Provider

- Wide variety of sensors and sensor systems portfolio as Sensor Solution Provider

- Sensors and Sensor Systems Product Information

- A comprehensive guide to information on Sensors and Sensor Systems from the TDK Group.

- Temperature Sensors (NTC) product Information

- A comprehensive guide to information on Temperature Sensors (NTC) the TDK Group

- Pressure Sensor Dies product Information

- A comprehensive guide to information on Pressure Sensor Dies the TDK Group