Product OverviewHigh frequency power inductors for automotive applications designed for outstanding reliability to reduce failure risks.

We are transitioning from an age where people drive cars to an age where people provide mobility services and utilize autonomous driving capability. As a consequence, the number of electronic parts used in cars is steadily rising. If even a single component fails, a specific function may be impaired, which as a result, severe performance requirements are placed on the components reliability. TDK provides high frequency power inductors for automotive applications that are designed for outstanding reliability to reduce failure risks.Contents

- Trends in car electronics

- Changing environmental demands for automotive parts

- Providing optimum solutions for various ECUs

- Product overview of high reliability, high frequency power inductors for automotive applications

- Product outline, features, and applications of high reliability, high frequency power inductors for automotive use

- Automotive power supply circuitry

- Contact

- Related Links

Trends in car electronics

Automobiles are expected to be safer and reduce environmental impact. Safety is created through a combination of functionality and automatization. ECU redundancy and function allocation are effective means for achieving high performance. The increase of xEV type cars (hybrids and electrical vehicles) is rapidly reducing the environmental burden. In step with these developments, the number of ECUs (electronic control units) is increasing, leading to stronger demand for electronic components, whose reliability, miniaturization and further performance improvements have become important requirements.

Changing environmental demands for automotive parts

As xEVs become more commonplace and autonomous driving is progressing, the demands placed on the reliability of components have undergone a change. The transition from internal combustion engines to vehicles with battery powered electric motors results in the disappearance of heat sources inside the car, thereby decreasing environmental temperature requirements, while autonomous driving on the other hand is expected to prolong the usage times of the vehicle. Environmental temperature requirements will be dependent on the respective functionality, and reliability requirements are expected to be around 3,000 hours. ECUs invariably make use of DC-DC converters to eliminate the influence of battery voltage fluctuations, while switching frequencies have been increased above the AM band to the region of 1.8 to 2.2 MHz as an EMI countermeasure.

Providing optimum solutions for various ECUs

Figure 3 shows a representative map of ECUs, with inductance as the horizontal axis and current as the horizontal axis. The HPL series is suitable for the high current / low inductance requirements of high power ECUs such as for ADAS (Advanced Driver Assistance Systems) image processing. The TFM series covers the medium range suitable for secondary circuitry of ADAS and other ECUs. The BCL series supports the high inductance values of low power ECUs for sensor and body applications etc. Our range of high frequency power inductor solutions optimized for automotive ECU applications perfectly meets the high reliability demands of this sector.

Product overview of high reliability, high frequency power inductors for automotive applications

The HPL, TFM, and BCL series of high reliability, high frequency power inductors further reduce failure risks with an emphasis towards the realization of level 5 autonomous driving. Compared to the metal-based power inductors for ICT applications, withstanding voltage and reliability characteristics have been further improved. The HPL series features high current / low inductance ratings, while the BCL series is designed for high inductance and low currents. The TFM series completes the lineup by covering intermediate requirements.

Product outline, features, and applications of high reliability, high frequency power inductors for automotive use

The HPL and BCL series are designed to minimize open-mode failure risks while the TFM series minimizes short-mode failure risks.

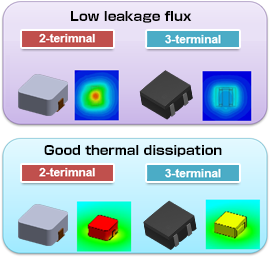

HPL products are characterized by low Rdc with small leakage flux. They are 3-terminal types with high vibration resistance and excellent thermal dissipation

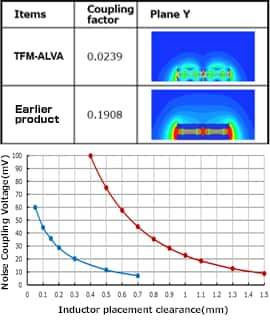

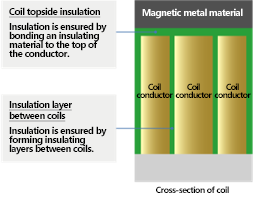

Featuring improved insulation of the metal material, the inductors of the TFM series are guaranteed to withstand voltages up to 40 V and can be used also in the battery line.. They realize low leakage flux and allow high density mounting.

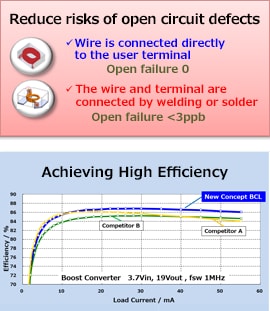

A new press method for the BCL series inductors minimizes the risk of wire damage. A low-loss magnetic material provides high efficiency for boost circuits with high magnetic flux. High inductance values are supported, making the inductors ideal also for circuits with a large potential difference between the input and the output.

| Series | |||

|---|---|---|---|

| External view |

|||

| High reliability feature |

No open-mode failure risk | No short-mode failure risk | No open-mode failure risk |

| Product outline |

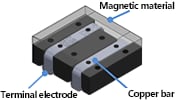

High current low inductanceConnection wire free structure with 1Ts copper bars serving also as user terminals. No risk of open-mode failure. Product is formed by sandwiching copper bars with ferrite core. |

Optimal for 2 MHz drive

Inductors based on thin-film process. |

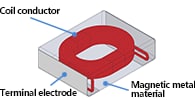

High inductance supportInductors with integrated wound coil of magnetic material. Metal bonding of winding to user terminals eliminates the risk of open-mode failure. Increased wiring area ratio allows also high inductance values. |

| Features |

|

|

|

| Usage |

|

|

|

| Product structure |

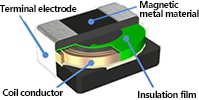

|||

| Structural features |

Using the copper bar as user terminal eliminates wire connection to realize high reliability | High reliability is achieved with the low pressure forming method that does not damage the wire | |

| Usage temperature range |

-55 to +155°C (including self temperature rise) |

-55 to +150°C (including self temperature rise) |

-55 to +155°C (including self temperature rise) |

| Magnetic material |

Ferrite magnetic material | Magnetic metal material | Magnetic metal material |

| Terminal electrode specification |

Copper bar + nickel (Ni) plating + tin (Sn) plating |

Conductive plastic + nickel (Ni) plating + tin (Sn) plating |

Conductive plastic + nickel (Ni) plating + tin (Sn) plating |

Automotive power supply circuitry

Figure 6 shows an example of an automotive power supply circuit. It can be used both in the primary and secondary circuit of the DC-DC converter configured in the ECU. The switching frequency on the secondary side is about 2 MHz. The HPL, TFM, and BCL series products offer optimal solutions in the area of high reliability, high frequency power inductors for automotive applications.