Explore Our Products

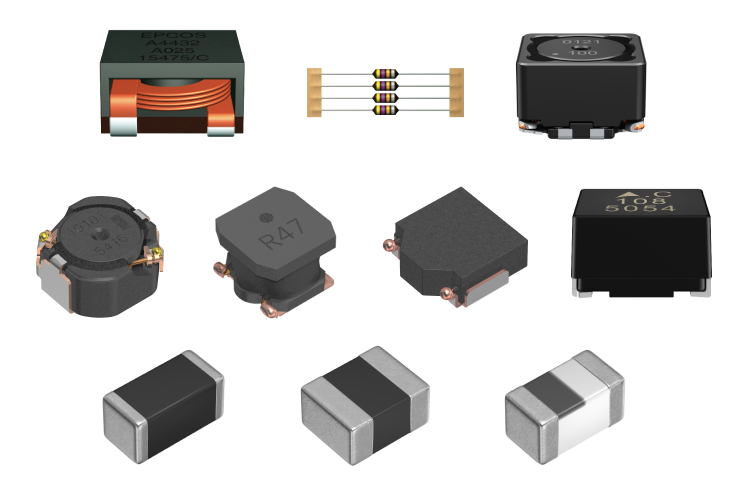

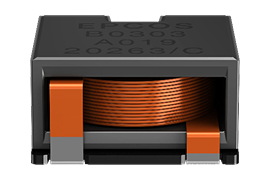

SMD / SMT Inductors (Coils)

Leaded Inductors (Leaded Coils)

Transponder Coils

High Current Flat Wire Inductors

Coupled Inductors

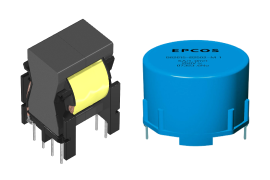

Choke Coils for PFC

Product Spotlights

See Our Featured Contents

Tech Notes

Take a Closer Look at Our Product Technology

News

Find Out What’s New

RSS Feed